Resources

Resources

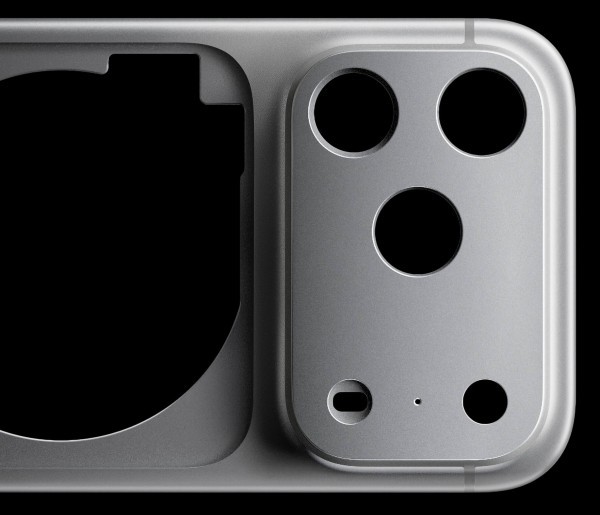

Aluminum chassis enclosure custom machining: Manufacturing Processes, Material Properties, Applications, and Advantages

What are the production methods for custom aluminum chassis enclosures?

Custom manufacturing of aluminum chassis enclosures can involve several different processes, each with its own benefits and suitable applications.

1. CNC Machining

Using computer numerical control (CNC) machines like milling and turning to remove material from a solid block of aluminum to achieve the desired shape and dimensions.

2. Die Casting

Injecting molten aluminum into a steel mold under high pressure, then cooling and solidifying it to form the part.

3. Sheet Metal Forming

Cutting, bending, stamping, and welding aluminum sheets to form the desired enclosure shape.

4. Extrusion

Forcing heated aluminum through a die to create long pieces with a consistent cross-sectional profile, which are then cut and further processed as needed.

5. Casting

Pouring molten aluminum into a mold and allowing it to cool and solidify, followed by machining and finishing.

6. Powder Metallurgy

Compressing aluminum alloy powder into a shape, then sintering it at high temperatures to create a dense, solid part.

7. 3D Printing (Additive Manufacturing)

Building parts layer by layer using selective laser melting (SLM) or electron beam melting (EBM) techniques.

The choice of custom manufacturing method for aluminum chassis enclosures depends on production volume, design complexity, cost considerations, and specific application requirements. CNC machining is ideal for high-precision and custom designs, die casting and sheet metal forming are suitable for high-volume production, while 3D printing offers unmatched design freedom and rapid prototyping capabilities. Selecting the most appropriate manufacturing process is crucial for ensuring product quality and cost-effectiveness.

YMP focuses on high-precision CNC machining aluminum enclosure customization for more than twenty years, the following focuses on the process of CNC machining of aluminum chassis enclosure and its advantages and applications.

What are the custom CNC machining processes for aluminum chassis enclosures?

1. CNC Milling

Process: Uses rotary cutters to remove material from a workpiece, creating complex shapes and fine details.

Advantages: High precision, suitable for complex geometries, and tight tolerances.

2. CNC Turning

Process: The workpiece rotates while a cutting tool removes material, ideal for cylindrical parts.

Advantages: High accuracy for round shapes, efficient for producing symmetrical parts.

3. Drilling and Tapping

Process: Creating holes and threading them for screws or bolts.

Advantages: Precise hole placement and consistency, essential for mounting components.

4. Multi-Axis Machining

Process: C machines that operate on multiple axes (e.g., 3, 4, 5-axis machines) to create complex shapes in one setup.

Advantages: Enhanced flexibility, reduced need for multiple setups, and ability to machine intricate designs.

5. EDM (Electrical Discharge Machining)

Process: Uses electrical discharges to remove material, especially useful for hard-to-machine shapes.

Advantages: High precision for intricate details, works well with complex geometries.

CNC machining aluminum chassis enclosures offers several advantages?

-

Precision and Accuracy

High Tolerance Levels: CNC machining can achieve very tight tolerances, ensuring parts meet precise specifications.

Consistency: Provides high repeatability, ensuring that each enclosure is identical to the design.

-

Design Flexibility

Complex Geometries: Capable of producing complex shapes and intricate designs that might be challenging with other manufacturing processes.

Customization: Easily accommodates design changes and custom features, making it ideal for prototyping and low-volume production runs.

-

Surface Finish

High-Quality Finish: CNC machining can produce a smooth surface finish, which can be further enhanced with anodizing, polishing, or painting.

Post-Processing Options: Allows for a variety of surface treatments, improving both aesthetics and functionality.

- Production Efficiency

Speed: CNC machines can operate continuously and produce parts quickly once the initial setup is completed.

Automation: High level of automation reduces the risk of human error and ensures consistent quality.

-

Material Utilization

Waste Reduction: CNC machining can be optimized to minimize material waste, which is both cost-effective and environmentally friendly.

Recyclability: Aluminum scrap generated during machining can be recycled, adding to the sustainability of the process.

Cost-Effectiveness for Low to Medium Volumes

Tooling Costs: Lower initial tooling costs compared to processes like die-casting or injection molding, making it cost-effective for small to medium production runs.

Setup Flexibility: Rapid setup changes allow for efficient switching between different designs or production batches.

- Enhanced Performance

EMI/RFI Shielding: Aluminum provides natural shielding against electromagnetic interference (EMI) and radio frequency interference (RFI), protecting sensitive electronic components.

Weight-to-Strength Ratio: Aluminum offers a good balance between weight and strength, making it suitable for applications where weight is a concern.

- Prototyping and Iteration

Rapid Prototyping: CNC machining is ideal for creating prototypes quickly, allowing for rapid design iterations and testing.

Low Volume Production: Efficiently handles low-volume production runs without the need for extensive tooling or setup.

- Versatility

Multi-Axis Machining: Capabilities of multi-axis CNC machines allow for complex and detailed work on multiple sides of the enclosure in a single setup.

Variety of Features: Can integrate various features like threaded holes, mounting points, and complex internal geometries directly into the enclosure design.

What are the material properties of aluminum chassis enclosure?

Strength and Durability: Aluminum offers excellent strength-to-weight ratio, making it strong yet lightweight.

Thermal Conductivity: Efficient heat dissipation is crucial for electronic enclosures, preventing overheating.

Corrosion Resistance: Naturally resistant to corrosion, further enhanced with anodizing or coatings.

EMI/RFI Shielding: Provides effective shielding against electromagnetic and radio frequency interference.

Machinability: Aluminum is relatively easy to machine, which reduces manufacturing time and costs.

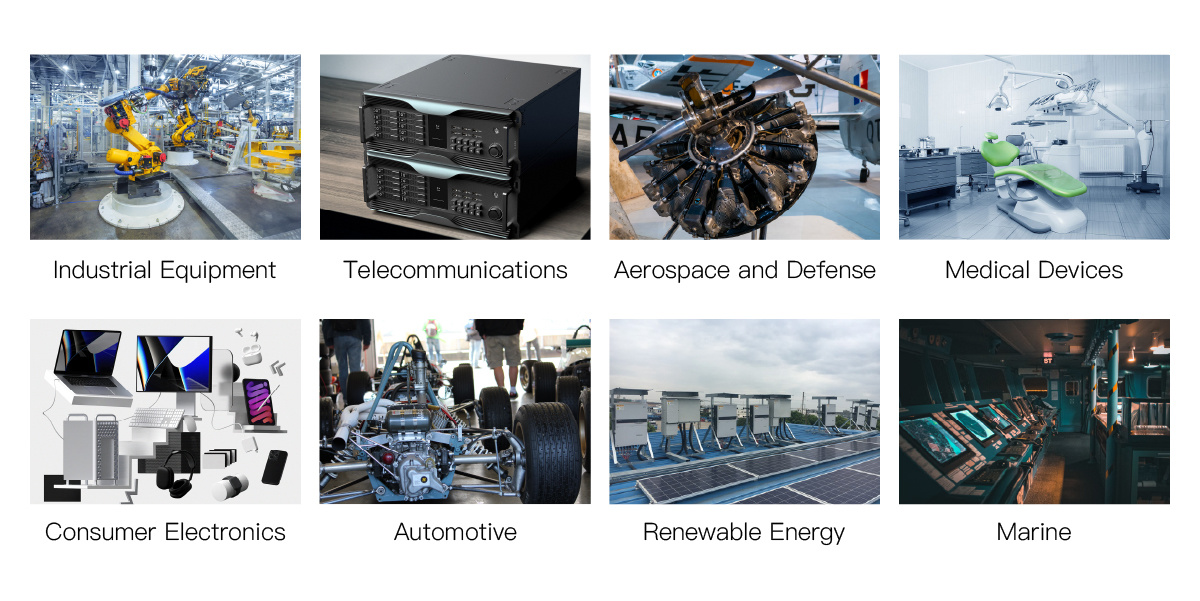

What are the application industries of aluminum chassis enclosures?

1. Industrial Equipment

Enclosures for control panels, machinery housings, and automation systems.

2. Telecommunications

Housings for networking equipment, servers, and communication devices.

3. Medical Devices

Protective enclosures for medical equipment and instrumentation.

4. Aerospace and Defense

Durable enclosures for avionics, radar systems, and military electronics.

5. Consumer Electronics

Custom cases for high-end audio equipment, gaming consoles, and home automation systems.

6. Automotive

Enclosures for automotive electronics, such as ECU housings and sensor covers.

7. Renewable Energy

Housings for solar inverters, battery storage systems, and wind turbine controllers.

8. Marine

Enclosures for navigation systems, communication equipment, and other marine electronics.

Custom machining of aluminum chassis enclosures leverages the precision and versatility of CNC processes to produce high-quality, durable, and precisely tailored enclosures for a wide range of applications. The material properties of aluminum, combined with the advantages of CNC machining, make it an excellent choice for industries that demand high performance, reliability, and customizability.YMP can provide high quality and high precision customized CNC machining service for aluminum chassis enclosure.

Aluminum chassis,Aluminum enclosure ,CNC machining,enclosure custom

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.