Resources

Resources

CNC Machining iPhone 17 Pro: Precision Milling of the Aluminum Unibody Frame and Global Manufacturing Insights

Introduction: The precision behind iPhone 17 Pro CNC machining

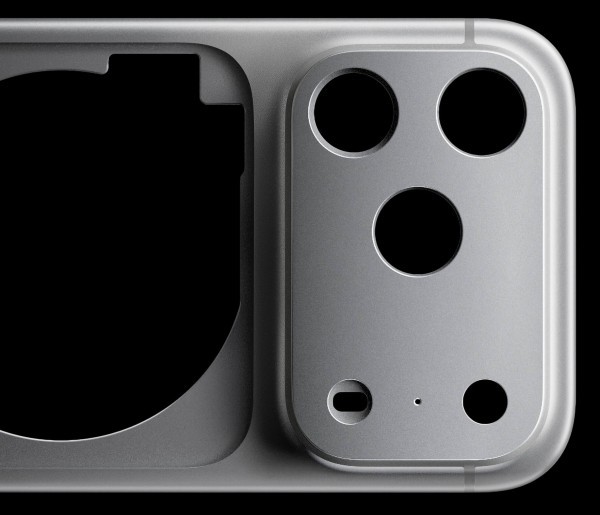

Apple continues its tradition of creating high-end products that combine aesthetics and engineering precision. One of the most complicated CNC machining processes used in consumer electronics is behind its seamless unibody aluminium frame. Precision milling the iPhone 17 Pro aluminium housing requires advanced 5-axis CNC machines, as well as tight tolerance controls, surface perfection and efficient global manufacturing strategies.

This article will examine how CNC machining gives the iPhone 17 Pro unibody case life. We'll also explore the benefits of aluminum alloys compared to titanium, as well as the challenges of manufacturing and the differences between China, India, Vietnam and Brazil in terms of CNC-machining capabilities.

1. What's so difficult about CNC Machining the iPhone 17 Aluminum Frame?

CNC milling iPhone 17 aluminum frame does not involve a simple metal cutting operation. It is a highly-controlled process that determines a device's weight, structure, and premium texture. Each unibody begins as a solid aluminum alloy block (commonly 7075 or 6063) and is then subjected to multiple stages of milling and polishing. This allows the housing to achieve its ultra-slim-tolerance, often less than +/-0.01mm.

The key challenges of CNC machining iPhone 17 Unibody Case include:

-

High dimensional precision:

The frame must be perfectly integrated with internal components such as the camera module or display. Assembly misalignment can be caused by a deviation of even 0.005 mm. -

Surface finish quality:

The iPhone 17 Pro’s matte brushed aluminium requires micro level surface polishing. This is often achieved by combining CNC machining, sandblasting, and anodizing. -

Complex Geometry:

Apple's unibody design with rounded edges introduces multiple internal cavities and undercuts that can only achieved by 5-axis milling. -

Heat Management:

Heat generated by the continuous machining of aluminium can cause thin walls to deform. It is important to control temperature and optimize toolpaths. -

Material Waste and Efficiency:

It can take several hours to machine a single iPhone housing, and remove over 90% of its original volume.

2. Aluminum Alloy or Titanium for iPhone Frames: Which is better?

Apple's decision to use aluminum in the iPhone 17 Pro unibody is strategic. It balances strength, weight and cost with machinability. Compare Aluminum alloys and Titanium Alloys in terms of CNC machining:

| Property | Aluminum Alloy (e.g., 6063, 7075) | Titanium Alloys (e.g. TC4, Ti-6Al-4V). |

|---|---|---|

| Density | ~2.7 g/cm3 (lightweight) | ~4.5 g/cm3 (heavier) |

| Machinability | High cutting speed | Low cutting speed; difficult to cut |

| Thermal conductivity | High (better heat absorption) | Low-cost |

| Surface Finish | Anodizing and polishing is easier | Additional finishing required |

| Cost | Buy Tickets Online | 5-10x higher |

| Ideal Application | Consumer electronics | Aerospace and medical |

While titanium is stronger, it's also harder to machine. This results in longer cycles and more tool wear. CNC-machining aluminum is the most efficient and best option for mass production of smartphone housings.

Apple is experimenting with Titanium for its premium editions because of its corrosion resistance and luxurious feel. The CNC machining of titanium requires specialized cooling systems and tooling, which are only available from top precision manufacturers.

3. CNC Milling is a key component in the production of iPhone 17 Unibody Cases

The CNC Milling iPhone 17 Unibody Case involves multiple coordinated processes.

-

Rough milling: Removal of bulk material from aluminum billet

-

Precision finishing: Achieving precise thickness and curvature with 5-axis machining.

-

Drilling & Slotting: Create ports, camera cutsouts and screw holes.

-

Edge polishing and deburring: Manual removal of burrs and automated removal.

-

Surface treatment: Anodizing and laser engraving are used to create Apple's matte finish.

Yixin Precision, a leading manufacturer, uses automated machine centers, and robot loading systems, to ensure efficiency and quality in real time. To verify tolerances, each step is monitored by coordinate measuring machines (CMM).

4. Aluminum Material Advantages for CNC Machining

Aluminum alloys used for CNC-machining iPhone 17 housing have several advantages.

-

Strong but lightweight: Ideal to maintain phone durability without adding bulk.

-

Excellent thermal characteristics: Prevents internal components from overheating.

-

High-quality corrosion resistance: Long-term reliability and appearance.

-

Anodizing Compatibility: Allows for a variety of colors and textures.

-

Aluminum is cost-effective. Compared with titanium or stainless steel aluminum provides great performance for the price.

Aluminum is a great choice for smartphones, but it's also a good option for aerospace, automotive, and robotic components.

5. Comparing CNC Machining Capabilities Globally by Country

Apple needs a large scale production, so the CNC machining is done globally. Here's a comparison of the key manufacturing countries:

China: The Global CNC Machining Hub

China is the dominant player because:

-

Supply chain for the entire industrial sector (from materials sourcing to surface finishing).

-

Machines with 5-axis CNC capability.

-

Highly qualified technicians and strict quality standards (ISO 9001, ISO 13485).

-

Fast delivery and competitive prices.

Shenzhen based manufacturers such as YIXIN Precision are experienced in machining aluminum housings and electronic components for aerospace and electronics clients.

India's Rapidly Emerging CNC base

India's CNC sector is growing, thanks to government initiatives and domestic demand.

Advantages:

-

Lower labor cost.

-

Growing the machining capability.

Challenges: -

China has less automation and precision than China.

Vietnam - Cost-Efficient Alternative

Vietnam is a major destination for investment by Apple's supply chains due to:

-

Proximity of China

-

Export and competitive labor policies.

-

Increased presence of CNC machining facilities specializing in small components.

High-end machining, such as iPhone unibody milling, still relies heavily on Chinese technical support and imported machines.

Brazil Regional Manufacturing Center

Brazil is focusing on localized manufacturing in Latin America.

Advantages:

-

The domestic electronic market is large.

-

Incentives for local production

Challenges: -

High raw material costs, and limited access CNC tools with high precision.

6. How YIXIN supports global CNC projects

As a leading CNC machining manufacturer in Shenzhen Yixin Precision offers one-stop solutions to CNC milling and turning, surface finishing and assembly.

We have a wide range of expertise in aerospace grade aluminum alloys that allows us to provide clients with a perfect finish and a rapid turnaround.

With 3 sets of 5-axis machining centers, ISO 13485 certification, and over 20 years of machining experience, YIXIN supports global clients from prototype to mass production--delivering the same precision Apple demands for its iPhone housings.

Conclusion

The CNC machining on the iPhone 17 Pro Aluminum unibody Case is a perfect example of the fusion of art and technology. Aluminum is the best material to achieve strength, beauty, and sustainability. CNC technology provides micron-level accuracy.

China is still the leader in high-end CNC production, but India, Vietnam and Brazil are reshaping global supply chains. Partnering with an experienced manufacturer such as YIXIN precision will ensure top-notch quality, on time delivery, and unparalleled technical support for brands looking to purchase premium-quality CNC-machined aluminum housings.

CNC Machining iPhone 17 PRO,CNC machining iPhone 17 aluminum frame,CNC milling iPhone 17 unibody case,CNC machining iPhone 17 housing, CNC milling and turning,CNC Machining, YIXIN precision

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.