Resources

Resources

Boosting Efficiency in Automated Production Lines with CNC Machining and Precision Fixtures

At today's fast-paced manufacturing landscape, demand for cost-efficient, precision solutions continues to skyrocket. Automated production lines have become the backbone of modern industry, helping companies increase output, improve consistency, and cut labor costs. At the core of their operation lie a network of essential components such as precision jigs, fixtures, and hydraulic manifolds manufactured through advanced CNC machining techniques - these essentials being essential components such as wire cut fixtures and hydraulic manifolds produced through this technique that are essential to system stability and productivity. In this article we explore why CNC machining plays such an integral role in supporting automated production lines while components like wire cut fixtures and hydraulic manifolds play an essential role in their operation and productivity.

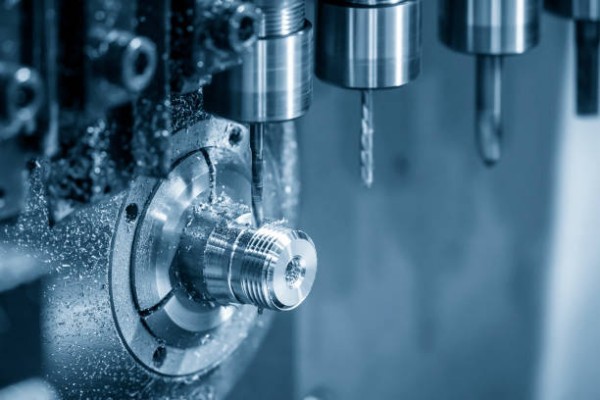

The Importance of CNC Machining in Modern Manufacturing

CNC (Computer Numerical Control) machining is a subtractive manufacturing method using pre-programmed computer software to drive tools and machinery movements, enabling highly precise, repeatable production of complex parts from materials such as aluminum, stainless steel, titanium and engineering plastics.

CNC machining serves a number of crucial purposes in automated production environments:

- High Precision:Jigs, fixtures and hydraulic manifolds require tolerances within microns for accurate performance; CNC machining provides this level of accuracy.

- Repetability: Once programmed into a CNC machine, parts can be replicated consistently across hundreds or thousands of cycles - something crucial for large production lines.

- Complex Geometry: Components such as wire cut fixtures often require intricate contours and close assembly that only CNC machining can reliably achieve.

- Material Versatility: CNC machining can handle a range of industrial materials, such as hard metals and engineering plastics found in jigs and fixtures.

Reasons Why Wire Cut Fixtures Are Essential

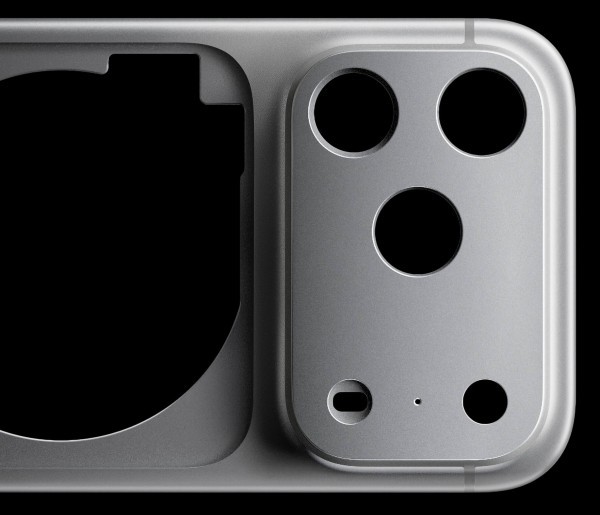

Wire EDM (Electrical Discharge Machining) fixtures are used to hold delicate components securely during cutting processes. Wire cut fixtures play an essential role in assuring precision cuts for manufacturing mold inserts, gears and electronic components.

Wire cut fixtures provide automated lines with:

- Secure Positioning: To prevent vibration or movement during machining and ensure consistent part quality.

- Faster Cycle Times: Well-designed fixtures reduce loading/unloading time and improve throughput, leading to faster cycle times and increasing throughput.

- Standardization: Utilizing the same fixture across multiple machines ensures uniform product dimensions.

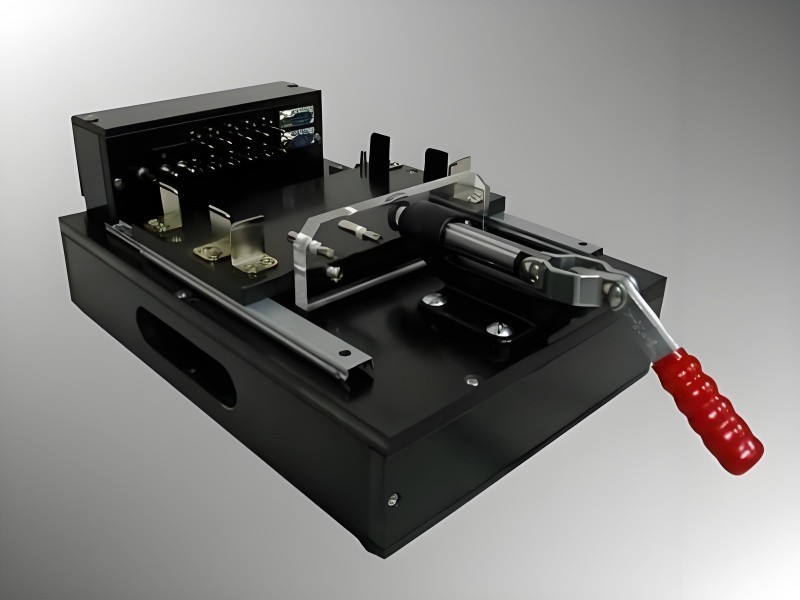

The Importance of Jigs and Fixtures in Automation

Both jigs and fixtures serve as workholding devices; however, their roles within automated production lines vary slightly:

Jigs provide accurate hole placement or machining path via precision drilling or routing tools, while fixtures keep parts securely in place, enabling high-speed, repeatable operations.

Automated systems rely on these components to eliminate human error, facilitate robot-based handling, and integrate smoothly into CNC processes. Jigs and fixtures specifically tailored for product shapes can often be made by 3-, 4-, or 5-axis CNC machining.

Key benefits include:

- Improved Accuracy: Lessening the risk of dimension variation during mass production.

- Reduced Downtime: Fixtures designed for quick setup support lean manufacturing.

- Increased Safety: Safe workholding can reduce risks related to accidents or machine damage.

Hydraulic Manifolds for Automated Systems: Coordinating Power

Hydraulic manifolds serve as fluid power control centers in automated production lines, managing flow and pressure between pumps, actuators, and valves. CNC machining is essential in creating their complex internal channels with pinpoint precision.

Features of CNC-machined hydraulic manifolds:

- Leakproof Design: Precise-machined sealing surfaces prevent fluid leakage.

- Compact Layout: Interieur Internal passages have been optimized to minimize footprint while still meeting flow rates.

- Reliable Operation: For high-pressure applications, excellent surface finishes and minimal tolerance variation are both essential, both of which can be achieved using CNC machining.

These manifolds are typically found in clamping systems, robotic arms and other high-force automation modules where stable and responsive hydraulic control are essential.

CNC Machining and Automation: An Unsung Partnership

CNC machining combined with automated production lines forms an unbreakable partnership: both parties benefit immensely from each other.

- CNC machining provides the jigs, fixtures and manifolds used by automated lines to run efficiently.

- Automated lines depend on consistently high-quality components in order to run effectively.

As industries such as automotive, aerospace, medical, and electronics strive to increase productivity while increasing quality control measures, demand for precisely machined support components will only continue to increase.

Why Select Shenzhen Yixin Precision?

Yixin Precision Manufacturing Co. Ltd.'s 20 years of experience in custom CNC machining and plastic/metal part production make them the go-to provider for global clients, offering everything from high tolerance jigs and fixtures, complex hydraulic manifolds, precision wire cut fixtures to complete one-stop solutions. Yixin offers complete one-stop solutions: from custom wire-cut fixtures to complex hydraulic manifolds - Yixin can deliver!

- Advanced Equipment: 3-, 4- and 5-axis CNC machining centers, EDM wire-cutting capabilities and CMM inspection.

- Rapid Prototyping and Mass Production: From sample development through full scale production support services - everything needed can be met here.

- Material Expertise: Aluminum, stainless steel, titanium, brass, engineering plastics, and more.

- ISO Certifications: Certified for quality (ISO 9001) and medical devices (ISO 13485).

- Global Support: Experienced export team and multilingual communication.

Yixin Precision can supply essential components that keep your automated production lines and new product launches operating at maximum performance, from upgrades to critical components that ensure smooth operations.

CNC machining,wire cut fixture,Automated Production Lines,jig and fixture,hydraulic manifold, jigs,fixtures ,Shenzhen Yixin Precision

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.