Resources

Resources

Plastic Paint: The Ultimate Guide to Flexible, Durable, and Professional Plastic Finishing

Today's industrial world is a very different place. Plastic paint It's more than a cosmetic touch. It is a protective coating that improves the appearance and durability of plastic components. From Automotive trims and housings You can also find out more about the following: Medical enclosures and industrial casings There are painted plastic components everywhere.

We at Yixin Precision understand the importance of selecting the correct plastic paint for your product. This will directly impact its performance, durability, and quality.

This article explains the basics of plastic spray paint. It also discusses flexible plastic paint and autoplastic spray paint.

1. Understanding the Importance of Plastic Paint

Plastic Paint is a specialized coating designed to adhere to polymer surfaces, such as ABS. PC, PVC. PP and nylon. Plastic Materials are different from traditional paints which adhere well to metals. They have smooth surfaces, low surface energy, and static charge. This makes standard paints susceptible to flaking or peeling.

Use Plastic Paint for the Following Benefits:

-

Surface bonding and improved adhesion

-

Chemical and UV resistance Enhanced

-

Color Retention and Better Scratch Resistance

-

The product has a premium finish

-

can be branded by using customized colors or textures

Plastic coatings are used in industries such as automobile and consumer electronic to improve the appearance of products, but also increase their lifespan.

2. Types of plastic paint used in industry

To achieve maximum flexibility and durability, different plastics need different paint formulations. Here are some of the most common categories that manufacturers, like Precision, use.

(1) Acrylic Plastic Paint

-

High gloss and color clarity

-

Ideal for decorative plastic components

-

Compatible with ABS, polycarbonate

(2) Polyurethane Paint

-

The renowned for their excellent chemical resistance and flexibility

-

is often used to trim the interior and exterior of automobiles

-

Compatible with flexible or soft-touch plastic parts

(3) Epoxy Plastic Paint

-

Highly durable and resistant against abrasion

-

The Best for Industrial Housings, Tools, and Mechanical Components

-

Use on rigid surfaces as it is less flexible

(4) Flexible paint

A Flexible Paint is an specialized formulation that can bend or flex along with the substrate, without cracking. This is particularly important for:

-

Car bumpers

-

Robot Covers

-

Protective casings

-

Wearable electronic shells

Flexible paints are made up of elastomeric Polymers, which allow the coating to be stretched and contracted while still maintaining adhesion.

3. How to paint plastic (step-by-step guide)

Paint plastic properly requires a precise surface preparation and the use of plastic primer. Here is the professional surface finishing process that YIXIN Precision uses.

Step 1: Surface cleaning

-

Use deionized or isopropyl Alcohol (IPA) to remove grease, oil and dust.

-

Avoid using harsh solvents as they can damage the surface.

Step 2: Sanding the Surface

-

Paint adhesion is increased by light sanding.

-

This helps to eliminate the mold release residue from injection-molded components.

Step 4: Prime

-

To ensure a strong bond, apply a primer for plastic adhesion.

-

Primer like chlorinated Polyolefin is ideal for PP and PE plastics.

Step 4: Paint

-

Use spray paint on plastic vehicles or flexible PU to ensure even coverage.

-

Keep a distance of 20-30 cm between the sprayer and the surface.

-

Use 2 or 3 thin coats instead of one thick layer.

Step 5 - Curing

-

Allow the paint to air dry at a controlled temperature (60-80degC, 30-60 minutes).

-

The right curing process ensures chemical bonds and color stability.

Step 6: Quality inspection

-

The thickness of the coating is usually 20-40 mm.

-

Test for adhesion and hardness.

4. Professional application of Auto Plastic Spray Paint in Automotive Parts

autoplastic spray paint is used extensively in automotive components such as bumpers, dashboards and interior trims. Its performance and aesthetics are both enhanced by this product.

The modern automotive grade paints have been designed to resist:

-

UV exposure

-

Stone chips

-

Extreme Temperature Changes

-

Fuel and Chemical Splashes

YIXIN Precision is a company that specializes in the custom machining and surface finish of automotive parts. Our auto plastic spraying process includes:

-

Paint booths that are dust-free

-

Robotic spray systems to ensure consistency

-

Flexible PU-based coatings on dynamic components

-

Metallic or matte finishes are available as an option.

This produces a durable OEM-grade finish which meets international automotive standards such as ISO 9227 or ASTMD3359.

5. The Key Factors to Consider When Choosing Plastic paint

| Factor | Description | You can also see our Example of a Good Way to Start |

|---|---|---|

| Adhesion | The bonding strength of the plastic substrate is determined. | Use CPO primer |

| Flexibility | Important for parts that are subjected to bending stresses | Paints based on silicone or PU |

| Durability | Resistant to UV, chemicals and abrasion | Epoxy or hybrid coatings |

| Finish Type | Metallic, glossy, metallic-look, or textured? | Depends on design intent |

| Application method | Spray, dip or brush | Spray painting is preferred for uniformity |

6. Plastic Paint Applications Across Industries

| Industry | Typical Plastic Parts | Coating Requirements |

|---|---|---|

| Automotive | Bumper, mirror cover, dashboard | Flexible, UV-resistant |

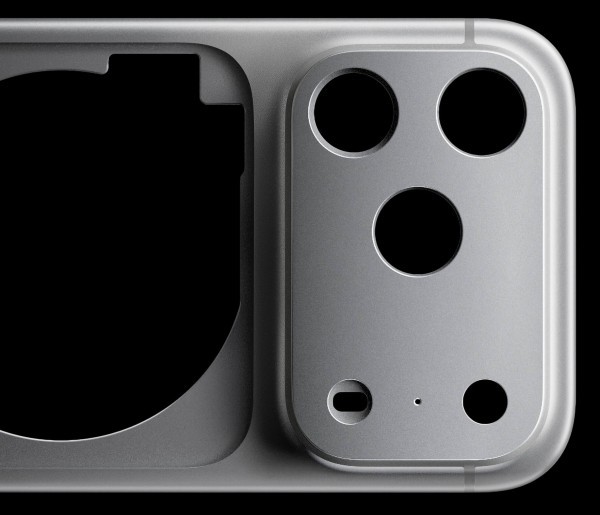

| Consumer Electronics | Camera housings and game controllers | Glossy or soft-touch |

| Robotics | Enclosures, joints | Flexible, scratch-resistant |

| Medical Devices | Handles and covers | Sterilization-resistant |

| Aerospace | Interior panels, sensors | Lightweight and durable |

7. What are the most common problems and how to avoid them?

| Problems with the? | Cause | You can also find out more about the solution by clicking here. |

|---|---|---|

| Peeling off or flaking | Insufficient surface prep | Use proper primer |

| Pinholes or bubbles | Trapped moisture (or dust) | Maintain a clean surface with controlled humidity |

| Cracking | Paint inflexible on flexible plastic | Use flexible paint formulations |

| Color fading | UV radiation | Use UV-resistant pigments |

8. Why choose YIXIN for painted plastic parts?

YIXIN Precision is a leading manufacturer of custom CNC machining parts and plastic components.

-

CNC machining + injection molding + surface painting

-

Material versatility (ABS, PC, PMMA, Nylon, PEEK)

-

Inspection of CMM & QC in-house

-

Small-batch and fast prototype service

-

ISO 9001 & ISO 13485 certified manufacturing

Our plastic paint service offers a complete solution, from machining to coating. This ensures that each surface meets the design and performance requirements.

Conclusion

Understanding the science behind flexible coatings and plastic paints will help you create components that look great and last longer.

You can always achieve a professional, smooth and durable finish with the right primer and paint.

If you are looking for how to paint plastic, or need CNC plastic parts finished with spray, YIXIN Precision can be your reliable partner when it comes to precision, quality and consistency.

plastic paint,flexible paint,best way to paint plastic,auto plastic spray paint,paint for plastic parts,plastic surface finishing,CNC plastic parts,YIXIN Precision

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.