Resources

Resources

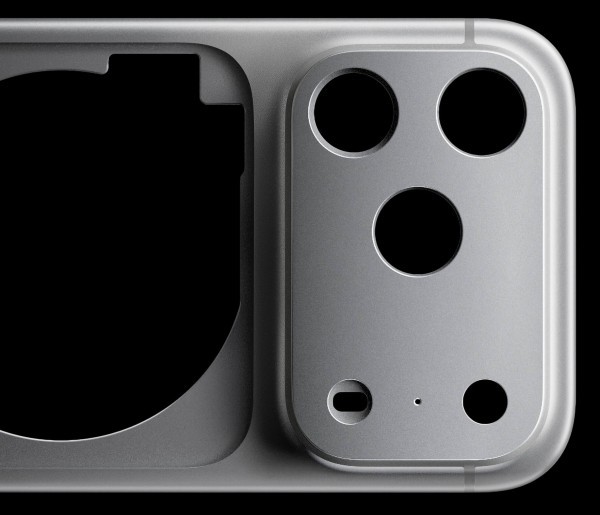

Mastering Aluminium Cut: Best Methods, Materials & Reliable Metal Cutting Services for Precision Manufacturing

Introduction

In the competitive landscape of CNC machining, achieving flawless aluminium cut results demands expertise in advanced techniques, material science, and reliable metal cutting services. As a trusted supplier in precision manufacturing, Shenzhen Yixin Precision combines cutting-edge technology with industry insights to deliver solutions tailored for aluminium sheets and complex metal components. This guide explores the best way to cut aluminium sheet, evaluates metal cutting materials, and highlights how partnering with certified experts optimizes efficiency and quality.

1. Advanced Metal Cutting Techniques for Aluminium

Aluminium’s lightweight, corrosion resistance, and thermal conductivity make it ideal for aerospace, automotive, and electronics industries. However, its softness and heat sensitivity require specialized metal cutting approaches:

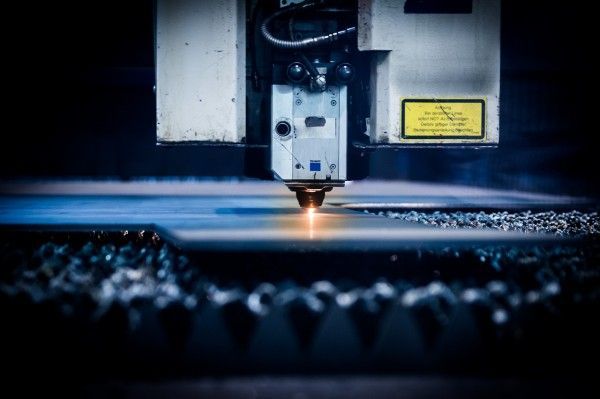

A. Laser Cutting: Precision for Thin to Medium Sheets

Applications: Ideal for intricate designs in 0.5–25mm aluminium sheets.

Advantages:

- ±0.1mm accuracy with smooth edges, minimizing post-processing.

- Minimal heat-affected zones (HAZ) using nitrogen assist gas to reduce oxidation.

- Limitations: Higher costs for materials >15mm.

B. Plasma Cutting: Speed for Thick Plates

Applications: Efficient for 5–50mm aluminium plates in industrial projects.

Advantages:

- 200+ IPM cutting speeds, ideal for bulk orders.

- Cost-effective for structural components like automotive frames.

C. Waterjet Cutting: Cold Cutting Versatility

Applications: Suitable for heat-sensitive alloys and thicknesses up to 200mm.

Advantages:

- Zero thermal distortion, preserving material integrity.

- Compatible with hybrid materials (e.g., aluminium-carbon fiber composites).

D. CNC Milling: High-Volume Precision

Applications: Custom shapes and tight-tolerance parts (e.g., aerospace brackets).

Advantages:

- Multi-axis machining (±0.05mm accuracy) for complex geometries.

- Supports high-strength alloys like 6061-T6 and 7075.

2. Best Way to Cut Aluminium Sheet: A Data-Driven Comparison

| Method | Thickness | Precision | Speed | Cost Efficiency |

| Laser | 0.5–25mm | ±0.1mm | Moderate | High (thin sheets) |

| Plasma | 5–50mm | ±0.5mm | Fast | Moderate |

| Waterjet | 1–200mm | ±0.2mm | Slow | Low |

| CNC Milling | 1–100mm | ±0.05mm | Moderate | High (bulk orders) |

Key Insight: For most projects, laser cutting balances speed and precision for sheets <15mm, while CNC milling excels in high-volume, complex parts.

3. Choosing Metal Cutting Materials for Optimal Results

Material selection impacts tool longevity and cut quality:

Aluminium Alloys:

- 5052-H32: High formability for automotive panels.

- 6061-T6: Aerospace-grade strength for structural components.

Tooling Solutions:

- CVD/PVD-coated carbide tools: Enhance wear resistance for high-speed milling.

- Diamond-coated blades: Reduce wear in laser/waterjet systems.

4. Partnering with Professional Metal Cutting Services

Selecting a reliable supplier like Shenzhen Yixin Precision ensures:

- Certifications: ISO 9001 and AS9100 compliance for aerospace-grade quality.

- Advanced Equipment: Fiber lasers, 5-axis CNC mills, and AI-driven systems for error-free operations.

- End-to-End Solutions: From CAD/CAM design support to post-processing (deburring, anodizing).

Case Study: A client reduced production costs by 18% using our CNC milling services for 6061-T6 aircraft brackets, leveraging multi-axis precision and rapid prototyping.

5. Industry Trends Revolutionizing Metal Cutting

- AI & Automation: Smart CNC systems optimize toolpaths, reducing scrap rates by 25%.

- Hybrid Techniques: Combining laser and plasma cutting for speed and edge quality.

- Sustainability: Recycling aluminium scraps and eco-friendly coolants to meet green manufacturing standards.

Why Choose Shenzhen Yixin Precision?

As a leader in metal cutting services, we offer:

1. Cutting-Edge Technology:

- 5-axis CNC machines and HNC-848D数控系统 for complex geometries.

- Fiber lasers with ±0.05mm tolerance for thin sheets.

2. Material Expertise:

- Proven solutions for 6061-T6, 7075, and exotic alloys.

3. Rapid Turnaround:

- 7–30-day delivery for custom parts, from prototypes to bulk orders.

4. Quality Assurance:

- 3D inspection reports and DFM analysis to prevent defects.

Conclusion

Mastering aluminium cut requires a synergy of advanced techniques, material knowledge, and trusted metal cutting services. Shenzhen Yixin Precision empowers manufacturers with precision CNC milling, laser cutting, and tailored solutions—ensuring efficiency, cost savings, and superior quality.

metal cutting ,aluminium cut,best way to cut aluminium sheet,metal cutting materials

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.