Resources

Resources

Unlocking Surgical Robot Precision: CNC Machining Cost Optimization with DeepSeek AI & Yixin Precision

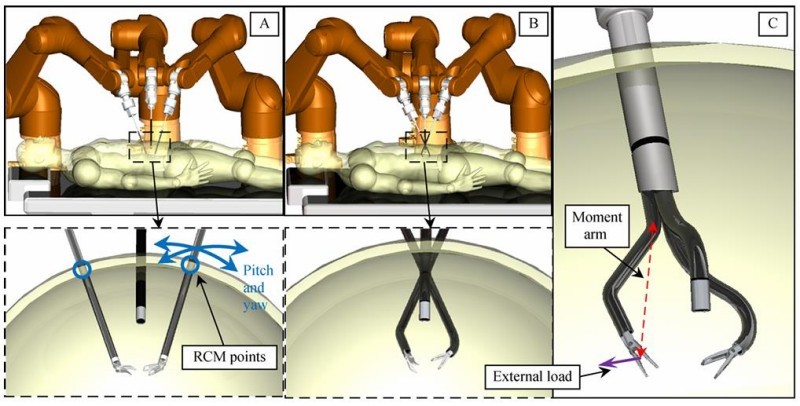

In the ever-evolving world of smart healthcare, surgical robots are reshaping how doctors perform operations. From minimally invasive procedures to remote-assisted surgeries, these advanced systems demand engineering excellence—and at the core of this revolution lies high-precision CNC machined components.

As robotic-assisted surgery becomes the new standard in complex procedures such as urology, gynecology, orthopedics, and neurosurgery, the mechanical arms, gearboxes, linkages, sensor housings, and actuator components that power these systems require unmatched precision, reliability, and consistency. These components are often manufactured through CNC (Computer Numerical Control) machining, an essential process for turning intricate 3D designs into real-world performance.

The Booming Market Behind Surgical Robotics

According to a 2025 deep industry report, the global surgical robot market is expected to grow from RMB 703.9 billion in 2021 to nearly RMB 4 trillion by 2030, with China alone reaching RMB 709.5 billion. This growth is fueled by factors such as:

Increased demand for minimally invasive surgery

Growing hospital investments in automation

Favorable clinical outcomes: reduced blood loss, fewer complications, and faster recovery

Integration with AI technologies like DeepSeek AI for smarter planning and real-time control

However, the precision and complexity of surgical robot systems mean that the machining of their components is not standard work—it demands next-level expertise.

CNC Machining for Surgical Robot Components: Why It’s Critical

Surgical robots such as the da Vinci system or domestic solutions like MicroPort and TINAVI rely on components that meet strict medical-grade requirements:

Micron-level tolerances: Often ±0.01mm or better

Biocompatible materials: Titanium, stainless steel (SUS316/304), PEEK, PTFE, and aluminum

High surface quality: Smooth finishes (Ra < 0.4µm) are critical to avoid biological contamination

Complex geometries: Multi-axis motion parts often require 5-axis simultaneous CNC machining

Heat-sensitive materials: Demanding low-deformation processes during cutting

Any deviation in size or material integrity can jeopardize the safety and precision of the surgical system, which is why manufacturers increasingly rely on CNC machining specialists for prototyping and production.

Cost Drivers in Surgical Robot CNC Machining

One of the biggest concerns for robot manufacturers and procurement teams is CNC machining cost. Understanding the cost structure helps in budgeting and supplier evaluation.

Key cost factors include:

Material cost: Medical-grade titanium and stainless steel can be expensive.

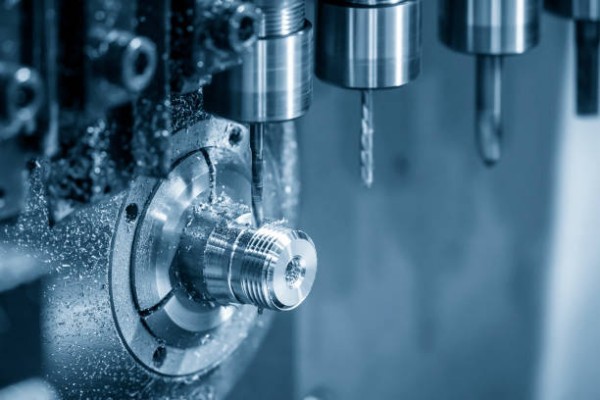

Machining complexity: 5-axis machining and tight tolerances increase programming and setup time.

Tooling and fixturing: Custom jigs may be needed for awkward geometries.

Inspection time: 100% dimensional reports, CMM inspection, and even CT scanning are sometimes required.

Batch size: Low-volume, high-mix orders typical in surgical robotics have higher unit costs.

How Yixin Precision Solves These Challenges

At Shenzhen Yixin Precision, we specialize in CNC machining of custom metal and plastic components, including high-end surgical robot parts. With over 20 years of experience, ISO 13485 certification, and a dedicated medical machining division, we are equipped to support rapid development and consistent production.

Our key advantages:

5-Axis CNC Machining Mastery

Equipped with multiple high-end 5-axis machines, Yixin can handle ultra-complex parts like surgical arms, jointed actuator mounts, and torque-optimized spline shafts with superior accuracy.

Medical-Grade Material Expertise

Our machining experts are familiar with the unique cutting characteristics of titanium alloys (e.g., TC4), stainless steels (SUS316L), and engineering plastics like PEEK and PPSU.

Quality You Can Trust

With ISO 13485 certification, every part undergoes full inspection protocols using CMM, optical vision systems, and surface roughness testers.

Rapid Prototyping & On-Time Delivery

We support design iterations with fast turnaround prototyping and DFM support. Parts highlighted for urgent shipment? No problem—we ship globally via air express.

Cost Transparency & Engineering Support

We offer clear CNC machining cost breakdowns, provide DFM advice, and work closely with engineering teams using DeepSeek AI-aided design data.

AI + CNC: A Smarter Future with DeepSeek

The integration of DeepSeek AI into surgical robot development marks a new phase of intelligent manufacturing. Yixin collaborates with R&D teams who use DeepSeek AI to generate optimized designs, simulate surgical paths, and reduce overengineering.

We transform those designs into reality with:

High-fidelity translation from AI-generated 3D models to machinable CAM programs

Machining simulation and collision avoidance verification

Materials traceability and post-processing integration (anodizing, polishing, passivation, etc.)

As the AI-driven medical device industry grows, the demand for agile, high-precision CNC manufacturing partners like Yixin Precision is skyrocketing.

Conclusion

Surgical robots represent the pinnacle of medical-mechanical innovation—and precision CNC machining is the backbone of their performance. From micro-tolerances to bio-safe materials, the requirements are extreme.

Whether you’re prototyping a new robotic joint module, producing connectors for a flexible surgical arm, or validating a DeepSeek AI-generated design—Yixin Precision is your trusted partner for CNC machining of surgical robot components.

Let’s build the future of robotic surgery—one precise part at a time.

CNC machining cost,surgical robot parts, Yixin Precision,DeepSeek AI

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.