Resources

Resources

What is the 5-axis CNC machining?

5-axis CNC machining refers to a type of computer numerical control (CNC) machining that operates on five different axes simultaneously. Unlike traditional 3-axis machining, which moves in three linear axes (X, Y, and Z), 5-axis machining adds two more rotational axes (A and B). This allows the cutting tool to approach the workpiece from multiple angles.

What are the X, Y, and Z axes in 5-axis CNC machining?

X axis: The X axis is the horizontal axis of the machining center, which controls the movement of the tool in the horizontal direction. The movement of X axis affects the lateral position of the processor and determines the position and shape of the processor in the horizontal plane.

Y axis: The Y axis is the longitudinal axis of the machining center, controlling the movement of the tool in the longitudinal direction. The movement of the Y axis affects the longitudinal position of the machining piece and determines the position and shape of the machining piece in the longitudinal plane

Z axis: The Z axis is the vertical axis of the machining center, which controls the movement of the tool in the vertical direction. The movement of the Z axis affects the height position of the processor and determines the position and shape of the processor in the vertical plane.

What is A,B axis in 5-axis CNC machining?

Axis A: Axis A is the rotation axis of the four axis and 5-axis machining center, controlling the rotation of the workpiece on the horizontal plane. The rotational motion of the A axis enables the workpiece to rotate around the vertical axis in the horizontal plane, thus achieving multifaceted machining.

C axis: The C axis is the rotation axis of the 5-axis machining center that controls the rotation of the workpiece on the axis perpendicular to the workbench. The rotation motion of the C axis allows the workpiece to rotate around the rotation axis in the vertical plane, thus realizing more complex multi-angle and surface processing.

Difference between 5-axis and three axis and four axis: Three-axis machining center

The three-axis machining center has three linear axes, usually X, Y and Z axes. They can control the tool to move in three directions, drilling and milling. Three-axis machining center is suitable for simple parts processing, such as plane parts, straight groove, etc.

Quad-axis machining center: Four-axis machining center has added an axis of rotation, usually A-axis. The rotational motion of the A axis can enable the workpiece to rotate around the vertical axis in the horizontal plane, thus realizing the multifaceted machining. The four-axis machining center is suitable for needs to be processed on different surfaces of the workpiece, such as inclined plane, inclined face, etc.

What are the types of 5-axis CNC machines?

- Swivel Head Type

- Dual Rotary Table Type

- Trunnion Table Type

- Gantry Type

- Robot Arm Type

- Moving Table Type

- Specialized Type

Advantages of 5-axis CNC machining?

High precision

The 5-axis machining center can realize the multi-angle and multi-plane processing of the parts through the 5-axis linkage mode, thus greatly improving the machining accuracy. This processing method avoids the accuracy error of the parts in different processing processes, and makes the processed parts more in line with the design requirements.

Flexibility of workpiece

5-axis processing process has extremely high flexibility and versatility, making it can adapt to the needs of different shapes, different sizes of workpiece processing requirements, so that the processing capacity and accuracy have been significantly improved. This flexibility and versatility makes the 5-shaft processing process widely used in aerospace, shipbuilding, automotive industry, medical equipment and other fields.

Processing multiple surfaces at the same time

The 5-axis processing center adopts dual station structure, and the clamp can be processed for 5-planes at a time, which reduces the error caused by multiple clamping and measurement, so as to improve the processing accuracy and efficiency, reduce the scrap rate and save the cost.

Machining complex surface

5-axis CNC machining center realizes the high precision machining of complex surface parts. The traditional processing method is difficult to qualify for the production of complex shape and high precision requirements. The 5-axis processing center, through multi-axis linkage, can complete the processing of multiple faces in a clip, realizing the accurate cutting of the complex surface of the workpiece, and ensure the accuracy and quality of the parts.

High production efficiency

through the linkage of 5-axis processing axis, the multi-side processing of complex parts, which can reduce the number of program Settings, clamping and process, so as to improve the production efficiency.

Optimization of cutting process

5-shaft processing process can reduce the cutting force and friction by optimizing the tool path and cutting parameters, thus extending the service life of the tool and reducing the manufacturing cost.

What are the application areas of 5-axis CNC machining?

5-axis CNC machining finds applications in a variety of industries due to its precision and versatility. Here are the primary application areas:

1. Aerospace

Components: Turbine blades, aircraft engine parts, structural components.

Characteristics: Requires high precision, strength, and lightweight structures; 5-axis machining handles complex geometries and tight tolerances.

2. Automotive

Components: Engine blocks, molds, turbocharger parts.

Characteristics: Demands high precision and complex shapes; 5-axis machining enables efficient, high-quality production.

3. Medical Devices

Components: Artificial joints, orthopedic implants, dental molds.

Characteristics: Requires extreme precision and smooth surfaces; 5-axis machining meets these stringent demands.

4. Mold Making

Components: Injection molds, casting molds, stamping dies.

Characteristics: Molds often have complex shapes and high precision requirements; 5-axis machining can complete these intricate shapes in fewer steps.

5. Energy Industry

Components: Turbine components, pumps, valves.

Characteristics: Requires high temperature resistance, corrosion resistance, and precision; 5-axis machining can meet these demanding standards.

6. Marine

Components: Propellers, hull components.

Characteristics: Involves machining large, complex parts; 5-axis machining provides efficient and precise solutions.

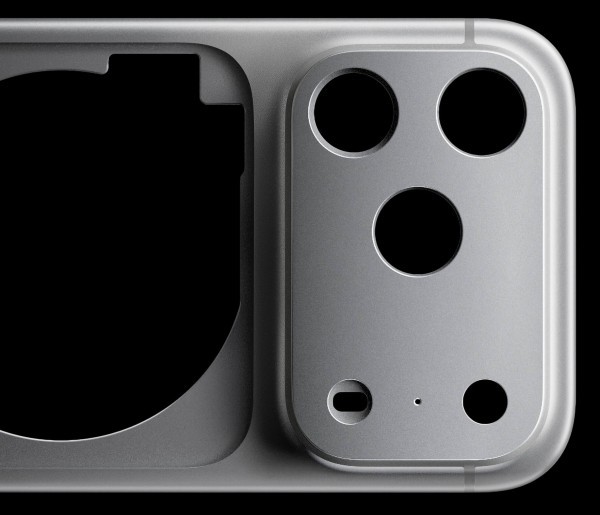

7. Consumer Electronics

Components: Smartphone cases, laptop housings.

Characteristics: Requires fine details and high precision; 5-axis machining can achieve complex curves and detailed work.

8. Model Making and Art

Components: Sculptures, models, intricate decorations.

Characteristics: Requires flexibility and complex geometries; 5-axis machining accurately realizes designers' creative ideas.

9. Defense

Components: Missile components, military equipment parts.

Characteristics: Demands high precision and reliability; 5-axis machining ensures the performance and quality of critical parts.

10. Avionics

Components: Electronic packaging, complex circuit boards.

Characteristics: Requires high precision and complex machining paths; 5-axis machining can meet these requirements effectively.

Overall, 5-axis CNC machining is widely used in industries that demand intricate shapes and high precision for their components.

Conclusion:

Machine tools are a symbol of a country's manufacturing level. On behalf of the highest level of the machine tool manufacturing industry is the 5-axis linkage CNC machine tool system. Yi Xin Precision & Plastic Co., Ltd (YMP) has a 5-axis CNC machining center and more than 20 years of experience in machining. YMP can use the 5-axis CNC machining center to produce high-end customized parts in aerospace, automotive, medical, shipbuilding, energy, precision equipment and other fields.

5-axis CNC machinin,CNC machinin,CNC, Custom Machining,CNC machined parts,machinery manufacturing,Custom CNC machining, CNC Machining Services, CNC Manufacturing, CNC Machined Parts

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.