Resources

Resources

CNC vs 3D Printing: Key Differences, Costs, Advantages, and Best Use Cases

In today’s manufacturing industry, the debate of CNC vs 3D printing is more relevant than ever. With the rise of additive manufacturing, many engineers and product designers wonder whether 3D printing vs CNC machining offers better efficiency, cost savings, and design flexibility. This article provides an in-depth comparison of both technologies, covering their advantages, limitations, costs, and application scenarios. We will also look at materials such as aluminum CNC machining and 3D printed carbon fiber vs carbon fiber components.

What Is CNC Machining?

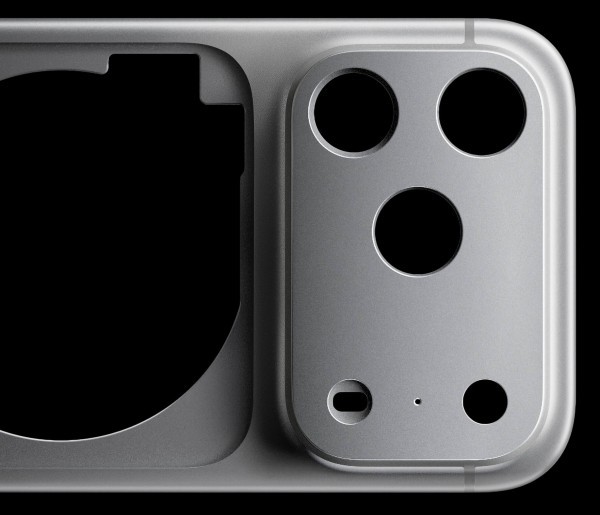

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block (often metal or plastic) to create a finished part. Common CNC operations include milling, turning, drilling, and grinding. CNC machining is widely used for high-precision components, including aerospace, automotive, robotics, and medical device parts.

Advantages of CNC Machining:

- High Precision: CNC machining achieves tolerances as tight as ±0.01 mm, ideal for functional and load-bearing components.

- Material Versatility: Works with metals like aluminum, steel, titanium, and plastics.

- Excellent Surface Finish: CNC parts have superior surface quality and durability without extensive post-processing.

- Best for Large-Volume Production: High repeatability makes CNC ideal for medium-to-high production runs.

What Is 3D Printing?

3D printing, or additive manufacturing, builds parts layer by layer from digital models. Unlike CNC machining, which removes material, 3D printing adds material to form the desired shape. Popular technologies include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

Advantages of 3D Printing:

- Design Freedom: Easily creates complex geometries impossible for CNC machining.

- Rapid Prototyping: Ideal for quick iterations and small-batch prototypes.

- Lower Tooling Costs: No need for molds or special fixtures.

- Lightweight Structures: Optimized infill and lattice designs reduce material use.

CNC vs 3D Printing: What Are the Key Differences?

When comparing CNC vs 3D printing, the main differences lie in the manufacturing approach, precision, material options, and cost efficiency. Below is a detailed comparison:

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Process Type | Subtractive (removes material) | Additive (builds layer by layer) |

| Material Options | Metals (aluminum, steel, titanium) & plastics | Plastics, resin, limited metals, composites |

| Precision | High (±0.01 mm) | Moderate (±0.1 mm) |

| Surface Finish | Smooth, ready-to-use | Rough, requires post-processing |

| Production Volume | Best for medium/high volumes | Ideal for low volume and prototypes |

| Setup Time | Moderate (toolpath programming) | Minimal (upload and print) |

3D Printing Cost vs CNC Machining Cost

One of the most common questions is: How does 3D printing cost compare to CNC machining? Generally:

- For prototypes or small batches: 3D printing is usually more cost-effective because it requires no tooling and less setup.

- For large production runs: CNC machining becomes more economical due to high production speed and lower material waste for bulk manufacturing.

Factors affecting cost include material type, complexity, quantity, and required precision.

3D Printed Carbon Fiber vs Carbon Fiber

3D printed carbon fiber vs carbon fiber is another important comparison in engineering applications. Traditional carbon fiber composites have superior strength and rigidity, making them ideal for aerospace and automotive components. On the other hand, 3D printed carbon fiber is a composite filament that incorporates chopped carbon fibers into a plastic matrix. While it improves stiffness and reduces weight compared to pure plastics, it does not match the performance of laminated carbon fiber sheets or CNC-machined carbon fiber parts.

In short, 3D printed carbon fiber is excellent for lightweight prototypes and functional parts under moderate stress, while traditional carbon fiber (or CNC-machined carbon fiber) is better for high-strength applications.

When to Choose CNC vs 3D Printing?

Here’s a quick guide:

- Choose CNC machining if: You need high-precision metal parts, excellent surface finish, and medium-to-large production volumes.

- Choose 3D printing if: You need a rapid prototype, highly complex geometries, or low-volume production with reduced upfront costs.

Aluminum CNC Machining: Why It’s Still Dominant

Aluminum CNC machining remains one of the most popular choices for industries like aerospace, automotive, and electronics. Aluminum offers an excellent balance of strength, weight, and corrosion resistance, and CNC machining ensures tight tolerances that 3D printing cannot yet achieve at scale. While aluminum 3D printing exists, it is far more expensive and slower compared to CNC.

Future Trends: Will 3D Printing Replace CNC Machining?

Many wonder if 3D printing will completely replace CNC machining. The short answer: No. Each technology has its strengths, and they will likely coexist. 3D printing will dominate in rapid prototyping and custom, complex designs, while CNC machining will remain essential for high-precision, high-strength, and high-volume manufacturing.

How Yixin Precision Can Help You

At Yixin Precision, based in Shenzhen, we specialize in aluminum CNC, stainless steel, titanium alloy machining, and advanced surface treatments. With over 20 years of experience, ISO-certified quality management, and one-stop services including CNC machining, sheet metal, die casting, and assembly, we help you choose the most cost-effective and high-quality manufacturing solution—whether CNC or 3D printing combined with CNC finishing.

Conclusion

The comparison of CNC vs 3D printing shows that both technologies serve different needs. For high accuracy and strength, CNC machining is unbeatable. For design flexibility and rapid prototypes, 3D printing leads the way. The future lies in leveraging both for maximum efficiency and innovation.

CNC VS 3d printing,3D printing VS CNC Machining,3d printed carbon fiber vs carbon fiber,3D printing cost,advantages of 3d printing,aluminum cnc

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.