Resources

Resources

Medical Device Machining and Implant Innovation:How CNC Technology Shapes the Future of Metal Implants and Biomaterials

Introduction: Why precision matters in medical device machining

The world of medical implant innovation is rapidly evolving. From hip replacement materials to advanced metal implants, the demand for highly precise, biocompatible, and reliable implantable medical devices continues to rise. Behind these innovations is the crucial role of CNC machining, which enables manufacturers to produce complex geometries, meet strict tolerances, and ensure the safety of patients worldwide.

This article explores how medical device machining supports the development of life-saving technologies, the importance of biomaterials and biocompatibility, and why suppliers like Shenzhen Yixin Precision are trusted partners in this industry.

The Role of CNC Machining in Medical Device Innovation

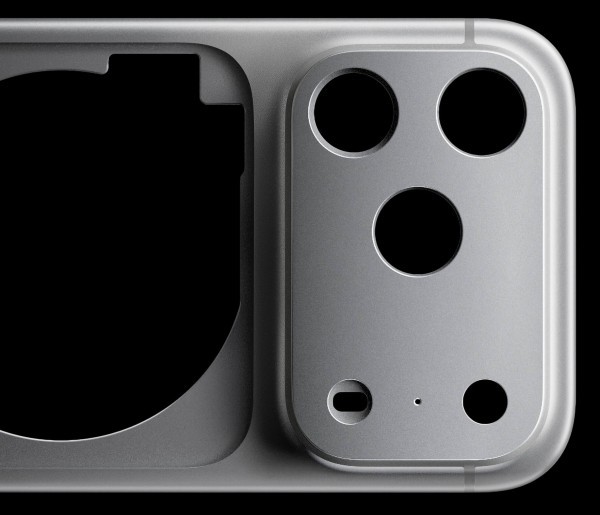

The CNC (Computer Numerical Control), machining is the mainstay of the medical device industry. Unlike traditional methods, CNC machining allows for extreme accuracy, repeatability, and scalability--critical when producing medical implants.

The following are some of the key advantages:

-

High precision tolerences for components such as bone plates, screws and joint replacements (upto +0.002 mm).

-

Complex Geometry Machining for customized implant tailored to the patient's anatomy.

-

Material Versatility enables the processing of titanium, stainless steels and advanced biomaterials.

Errors are not tolerated in medical applications. CNC machining is used to ensure that all parts meet regulatory standards including ISO 13485 for medical devices.

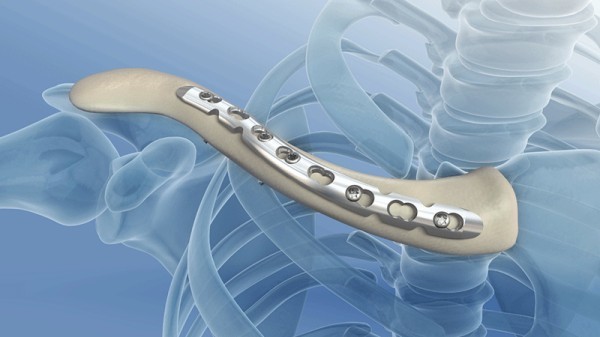

Materials driving hip replacements and metal implants

The material used to make an implant determines its success and durability. hip materials, for example, are made of titanium alloys (Ti-6Al-4V), or cobalt chrome due to their corrosion resistance and strength. The CNC machine allows these materials to be shaped into implants with precision without compromising their performance.

The following are other commonly used metallic implants:

-

(316L) Stainless Steel is durable, affordable and used widely for screws and plates.

-

Titanium Alloys are lightweight, strong and highly biocompatible. They're perfect for implants that need to carry loads.

-

Cobalt and chrome alloys are known for their wear resistance.

Biomaterials in Implantable Devices: Biocompatibility and Biomaterials

Modern implants medical devices should integrate seamlessly into the human body. Not only does this require robust engineering, but also careful materials selection. Biocompatibility is the ability to ensure that implants will not cause adverse immune reactions, infection, or rejection.

The CNC machine can be used to process advanced biomaterials such as:

-

PEEK for spine implants.

-

Porous titanium structure which promotes bone integration.

-

Surface-treated Alloys to improve osseointegration.

Combining CNC precision and biomaterial innovation allows manufacturers to create implants that are more durable and better for patients.

Medical Implant Innovation: Customization is the Future

Customization is one of the most important trends in innovation. CNC machining allows for patient-specific implants based on 3D scanning, instead of one-size fits all implants. It not only enhances implant functionality but also improves patient comfort and recovery time.

Future advances are likely to be focused on:

-

Smart implants with sensors to monitor healing

-

Hybrid Biomaterials combining metal strength and polymer flexibility.

-

Additive Manufacturing + CNC Hybrid Workflows where 3D-printed structure are finished with CNC precision.

Shenzhen Yixin Precision - a trusted partner in medical device machining

We have over 20 years experience in the field of CNC Machining for Implantable Medical Devices. Our capabilities include:

-

ISO 13485:2016 certified production processes.

-

Experience in the machining of titanium alloys and stainless steel.

-

CNC five-axis machining complex geometries for orthopedic and dental implants.

-

One stop service includes machining, surface treatments, inspection and assembly.

Yixin Precision works with international medical companies to ensure that every component meets international standards and provides cost-effective solutions of high quality.

The conclusion of the article is:

The future of Medical Device Machining will be full of innovation, from Hip Replacement Materials to the next-generation Biomaterials. CNC machining transforms ideas into durable and effective implants. Companies like Shenzhen Yixin Precision, with their expertise in precision manufacturing and medical device design, are shaping the future of implantable devices around the world.

Medical Device Machining,medical implant innovation,hip replacement materials,,Metal Implants,Implantable medical devices,Biomaterials,Biocompatibility,CNC machining

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.