Resources

Resources

7 Powerful Things to Know About Sheet Metal: What Is Sheet Metal, Types, Finishing & Precision Fabrication

Sheet metal is a versatile material used in modern manufacturing. Sheet metal is used in a variety of products, from metal enclosures to protect electronics to complex automotive panels and precision housings. This guide--written from the perspective of an experienced hardware and plastic parts manufacturer--explains what is sheet metal, the main types of sheet metal, common sheet metal finishing options, how sheet metal fabrication processes work, the role of automotive sheet metal, and why precision sheet metal fabrication matters. This article is easy to read and authoritative. It is a great resource for manufacturers, designers, engineers and procurement specialists who are looking for clear, actionable information.

What is sheet metal?

Sheet Metal is a flat, thin piece of metal that can be bent, cut, and formed into parts. The thickness of sheet metal can vary widely, from very thin foils to heavy gauge sheets. It is measured in millimeters and gauge numbers. Steel, stainless steel and aluminum are all common sheet metal materials. Copper, brass and specialty alloys are also available. Sheet metal is a versatile material that offers structural strength and repeatability in thin sections.

Why use sheet metal?

-

High strength to weight ratio (especially for aluminum and stainless steels).

-

Cost-effective for medium and high volumes

-

Join, form and surface-treat easily.

-

The material is ideal for brackets, enclosures, panels, and chassis.

Types of sheet metal

Understanding types and properties of sheet metal will help you choose the best material for your needs, including cost, function, and manufacturing.

-

Cold rolled steel (CRS). Good surface finish and dimensional stabilty; commonly used in painted parts, chassis and brackets.

-

Hot-rolled Steel (HRS) Thick and cheaper; used when surface finish is not as important.

-

Stainless Steel (e.g. SUS304,SUS316) Corrosion resistant; typical for medical, food and marine applications.

-

Aluminum (e.g., 5052, 6061)

Widely used in consumer electronics, automotive and aerospace. Lightweight, corrosion-resistant. -

Copper or brass

Decorative finishes and excellent electrical conductivity; used on electrical components and trim. -

Pre-painted and galvanized metal

Steel coated to resist corrosion, or pre-finished to speed up assembly and meet aesthetic needs.

The choice between these types is a compromise between cost, weight and corrosion resistance.

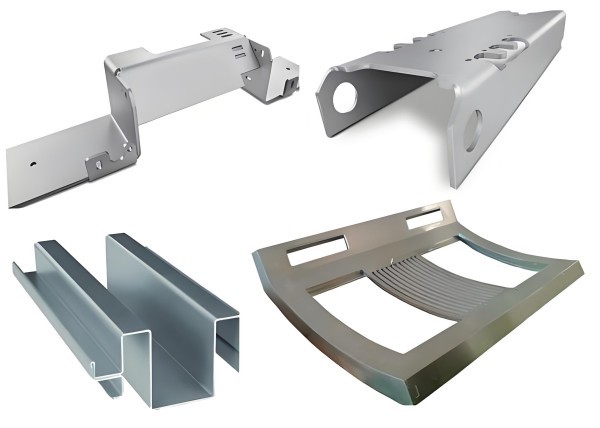

Sheet metal fabrication processes - how parts are made

Sheet Metal Fabrication Processes convert flat sheets into finished components. The most common steps are:

-

Design and CAD/Nesting : Parts are designed using CAD software; nesting software arranges the parts on sheets in order to minimize waste.

-

Cutting: Waterjet, laser cutting, plasma cutting and turret punching are all common methods. Laser cutting is perfect for thin gauges to medium gauges. Waterjet cuts are free of heat-affected areas.

-

Bending/Forming : Press brakes and automated bending cells bend parts to angles or curvatures specified.

-

Deep Drawing/Stamping: For large-volume parts, stamping and progressive dies can create complex shapes quickly.

-

Joining & Welding: Spot welding, MIG, TIG and rivets are used to join components together.

-

Machining and Secondary Operations: CNC turning or milling adds features or cutouts with tight tolerances that are not possible by forming alone.

-

Assembly & Testing : Fasteners and gaskets are used to ensure that parts meet specifications.

Each process has an impact on tolerances, cost, lead time, and surface finish. Combining methods (e.g. laser cutting + CNC secondary machine) supports precision metal fabrication when tight dimensions and critical fit are required.

Sheet metal finishing - enhance durability and aesthetics

Sheet Metal Finishing is essential for corrosion protection, appearance and functional properties.

Common finishing options

-

Powder coating: Durable, uniform finish for indoor/outdoor use.

-

Electroplating: Nickel, zinc, chrome: Protects or enhances conductivity.

-

Anodizing: Increases corrosion resistant and allows color finishes.

-

Passivation: Removes surface contaminants, improves corrosion resistance.

-

Paint & Liquid Coatings : Flexible and cost-effective custom colors.

-

Beadblasting / polishing : Controls surface gloss and texture.

-

Galvanizing : Hot-dip zinc coating to provide superior corrosion resistance.

The right finish to use depends on the environment, regulatory requirements, (e.g. RoHS, medical standards), as well as expected lifecycle.

Automotive sheet metal - trends and demand

Automotive sheet Metal components include body panel, brackets and subframes. Automotive applications demand:

-

High repeatability with tight tolerances Panel gaps and fit.

-

Weight Optimization (use aluminum, high-strength alloys) for fuel economy.

-

Crashworthiness (advanced steels with high strength) and energy absorption.

-

Surface quality for visible bodywork.

-

Reliability of the supply chain and quick lead times for model updates.

The use of aluminum and tailored metal blanks, laser welding to reduce weight, and integration into metal enclosures are all emerging trends.

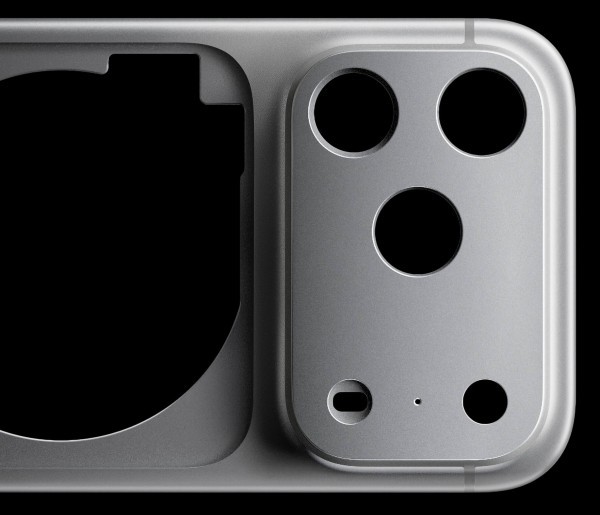

Metal enclosure design -- practical tips

Metal enclosures protect electronic and mechanical components. Best practices:

-

Design for Manufacturability: Minimize deep draws, reduce tight internal radiuse, and standardize the fastener locations.

-

Use vents, conductive mounting or integrated heat sinks to plan for thermal management.

-

Ensure EMI/RFI shielding for sensitive electronics--consider conductive finishes or gasketing.

-

Use pre-threaded inserts and snap features to optimize assembly.

Well-designed enclosures can reduce assembly time while improving product reliability.

Precision sheet metal fabrication - when it counts

Precision Sheet Metal Fabrication is the production of parts with tight dimensional tolerences, repeatable fit, and high surface qualities. This is crucial for industries like aerospace, medical devices and semiconductor equipment.

Key elements in precision fabrication

-

High-accuracy CNC and press brakes, with automated crowning and tool compensating.

-

In-process inspection: CMM check, optical measurement and first-piece studies.

-

To ensure consistency, strict process control and documentation is required (PPAP, FAI).

-

Surface treatments and controlled material traceability that comply with industry standards.

To achieve the required tolerances and geometries, precision fabrication often combines sheet-metal forming with secondary CNC machining on 3- or 4-axis machines.

What to look for when choosing a sheet metal partner

Prioritize the following when selecting a supplier of sheet-metal fabrication or high-precision sheet-metal fabrication:

-

Experience in your industry (automotives, medical, aerospace)

-

We offer a wide range of processes: cutting, bending and welding, machining and finishing.

-

Quality systems and certifications.

-

Capacity to prototype and produce small batches plus scalable volume runs.

-

Local engineering support to DFM, tolerance negotiations, and cost optimization.

Why choose Yixin Precision?

Yixin Precision offers a complete solution, from prototyping through to assembly. Key advantages:

-

Comprehensive capabilities CNC machining and sheet metal fabrication. Die casting, injection molding and surface treatment.

-

Precision equipment Multiple five-axis machines (third in 2024), and dedicated sheet metal fabrication line for reliable precision.

-

Medical industry experience: ISO 13485 certified -- qualified to handle medical devices components and other regulated components.

-

Small batch & fast turn expertise: Optimized processes for quick prototypes, low-volume production and quality without sacrificing.

-

Quality assurance : In-process inspection (inspections), material traceability (traceability of materials), and FAI/PPAP ready documentation.

-

Global Service: Experience supporting clients in robotics, automotive and aerospace, medical and consumer electronics, with both domestic and global supply chains.

Yixin Precision can provide you with metal enclosures or automotive sheet-metal components. We also offer precision sheet-metal fabrication.

what is sheet metal,types of sheet metal,sheet metal finishing,automotive sheet metal,metal enclosure,sheet metal fabrication processes,precision sheet metal fabrication

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.