Resources

Resources

Precision Unleashed: The Wire EDM Revolution in Modern Machining

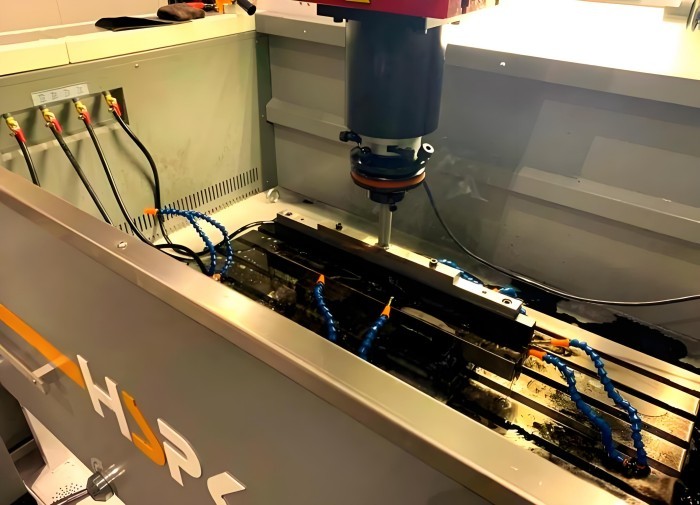

Wire Electrical Discharge Machining (Wire EDM) has long been recognized as an innovative process in precision manufacturing. Utilizing controlled spark erosion, it cuts conductive materials with incredible accuracy--perfect for complex geometries, hardened alloys, and micro features not possible with traditional tools. A thin wire EDM wire made of brass or coated wire acts as an electrode while dielectric fluid flushes debris out while cooling the workpiece - unlike mechanical cutting which exerts contact force causing distortion to delicate or thin-walled parts compared with wire EDM's zero contact force eliminates distortion thus eliminating distortion compared to mechanical cutting which exerts contact force thus eliminating distortion completely in delicate or thin-walled parts alike!

Fast Walking Vs Slow Walking Wires: A Technical Breakdown

Fast Walking Wires (Reciprocating):

These fast walker wires typically operate between 8-12 meters per second with reusable molybdenum wire, at speeds of 8-12 m/s. Although cost-effective, wire vibration may limit tolerances to +-0.02mm while surface roughness falls between Ra 1.6-3.2 mm. Traditionally used in China for general-purpose tooling and prototyping.

Slow Walking Wires (Low-Speed One-Way):

For low speed one way systems, single pass brass wire walking at 0.2 meters per second combined with deionized water dielectric and constant tension can achieve +-0.005mm tolerances and Ra 0.4 mm after multiple cuts; ideal for aerospace and medical device manufacturing applications.

Hybrid Medium Speed Systems:

Combine initial high-speed roughing with slow finishing passes. This boosts efficiency while nearing slow-wire precision—ideal for mold inserts and gears.

Wire EDM Wire and its Importance EDM wire isn't designed to be interchanged; rather it must be engineered specifically to provide spark resistance and consistency in its output. Brass wires (CuZn37/CuZn40) typically offer the greatest spark resistance and consistency; their diameter range ranges between 0.1-0.30 mm with Tensile Strength of up to 1,180 N/mm2 to resist snapping of wire ends.

Conductivity: 22-24% IACS for efficient spark generation

Advanced coated wires such as zinc-fused versions reduce breakage during intricate cuts further.

Wire Cut Fixture: Stability Equals Precision Its A solid wire cut fixture is essential to achieve tolerances under 5 microns, with key design principles including non-conductive composite materials to avoid arcing.

Clamping: Low-stress vises prevent part deformation during long operations.

Modularity: Quick swaps enable batch processing of electrodes or medical components. Fixtures enable complex cuts - like tapered turbine blades or 1,000 mm-thick tooling-- without compromising accuracy.

Mastering Wire EDM Tolerances and Surface Finish

Wire edm tolerances depend on machine class and process control:

|

Capability |

Fast Walking Wire |

Slow Walking Wire |

|

Positional Accuracy |

±0.015 mm |

±0.002 mm |

|

Surface Roughness |

Ra 1.6–3.2 μm |

Ra < 0.4 μm |

|

Minimum Kerf |

0.20 mm |

0.15 mm |

Edm surface finish can be dramatically enhanced through multi-pass strategies. In critical applications, adding nano-powder additives such as Al2O3 to dielectric fluid can significantly decrease roughness by 35% while simultaneously speeding material removal.

Modern EDM Spark Erosion Machines Range from Benchtop to Gantry

Modern EDM Spark Erosion Machines span from benchtop models such as the SFX-4000B (800W-3,000W), which extract broken taps without disassembling components, to portable units like the SFX-4000B Portable Unit for quick tap extraction in minutes without disassembly.

- CNC-Controlled Giants: Multi-axis systems capable of creating 3D contours using G-code (G0-G3, M3/M30). Dielectric fluid plays an essential role here;Macron EDM 110 boasts high purity and low conductivity to protect nonferrous metals from electrolytic corrosion.

Applications: Where Wire Cutting Machines Excel

Wire cutting machine applications reveal their versatility:

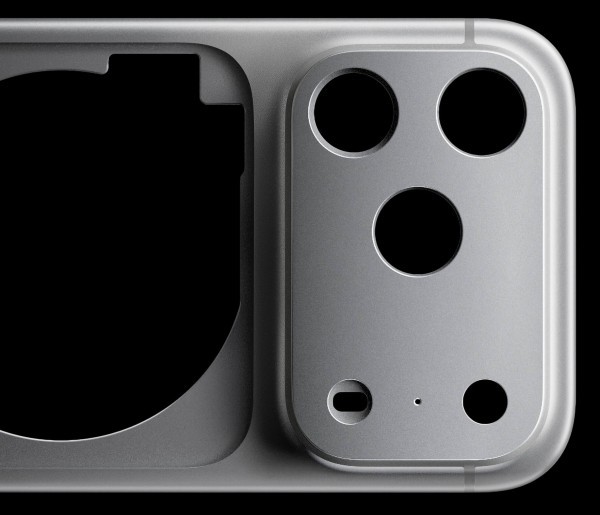

Mold & Die: Cutting carbide stamping punches or injection mold cores with <5-μm taper error

Medical: Crafting bone-saw blades made of stainless steel with biocompatible edges for medical applications.

Aerospace: Slitting nickel alloy turbine disks using wire edm wire with diameters as small as 0.10 mm for aerospace turbine disks.

Laser-assisted systems such as Laselec ILC Bench Top can now integrate with EDM for hybrid processes like stripping coaxial cables before contact machining.

Future Innovations: Automation and AI

Self-Threading Wires: Automatic wire rethreading during multi-hour cuts.

Adaptive Spark Control: AI adjusts voltage and pulse frequency real time to prevent wire breakage--even with 0.10mm wires!

Eco-Dielectrics: Recyclable synthetic oils reducing disposal costs by 40%.

The Strategic Edge

Wire EDM is revolutionizing precision manufacturing. By carefully choosing between cost-driven fast-walking or precision slow-walking wire types and pairing them with sophisticated fixtures and tolerancing protocols, manufacturers are now achieving results traditional methods couldn't. At Shenzhen Yixin Precision, we take advantage of these nuances to deliver components with less than micron deviation - something traditional methods cannot do.

wire edm,wire edm wire,wire cut fixture,wire edm tolerance,edm spark erosion machine,wire cutting machine,edm surface finish,Fast walking and slow walking wires

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.