Resources

Resources

Understanding the Surface Treatment Process: Identifying and Preventing Anodizing Defects in CNC Machining

Introduction

In CNC machining, the final appearance and durability of parts often depend on a critical post-processing step—surface treatment. Among various techniques, anodizing is widely adopted for aluminum and titanium components due to its corrosion resistance, aesthetic versatility, and ability to enhance surface hardness. However, even a well-controlled surface treatment process can lead to anodizing defects that compromise functionality and appearance.

This article explores the types of anodizing, common anodising defects, and how CNC machining manufacturers can optimize their processes to avoid them.

1. What Is Anodizing in CNC Machining?

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. It is particularly popular for aluminum alloys used in precision components in industries such as:

- Aerospace

- Medical devices

- Electronics

- Robotics

- Optics

There are different types of anodizing, including:

- Type I (Chromic Acid Anodizing) – Thin coatings for corrosion resistance

- Type II (Sulfuric Acid Anodizing) – Most common, used for decorative and functional applications

- Type III (Hard Anodizing) – Thicker layer for wear resistance in harsh environments

2. The Surface Treatment Process in Anodizing

The surface treatment process for anodizing includes multiple steps:

- Pre-cleaning: Removal of oils, greases, and oxides

- Etching or brightening: Optional step to improve texture or luster

- De-smutting: Removing residues from etching

- Anodizing: Electrolytic process using acid baths and electric current

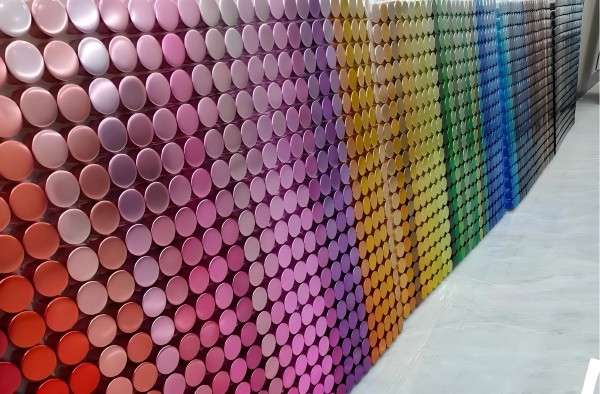

- Dyeing (optional): Adding color to the oxide layer

- Sealing: Hydrating the porous layer to close it and enhance corrosion resistance

Every stage requires tight process control to prevent anodizing defects.

3. Common Anodizing Defects and Their Causes

Even small deviations in process parameters can lead to anodising defects that affect product quality. Below are the most frequently encountered issues:

| Defect Name | Description | Common Causes |

| Color Variation | Inconsistent color or uneven shades | Improper current density, uneven surface prep |

| Pitting or Corrosion | Small holes or corrosion marks | Incomplete cleaning, contaminated bath |

| Burn Marks | Dark or blackened spots on the surface | Excessive current or contact issues during anodizing |

| Streaking | Linear marks or smudges after anodizing | Improper racking or inconsistent etching |

| Peeling or Flaking | Oxide layer separates from the base metal | Poor adhesion due to surface contamination |

| Chalking | Powdery appearance post-anodizing | Inadequate sealing or over-etching |

| Smutting | Dark residues on aluminum surface | Incomplete de-smutting step |

| Blistering | Bubbling or raised areas | Entrapped gases, high bath temperature |

4. CNC Machining Best Practices to Prevent Anodizing Defects

To reduce the risk of defects, CNC machining manufacturers should consider:

Precision Surface Preparation: Deburring, polishing, and cleaning are essential pre-treatments

Material Consistency: Use anodizing-grade aluminum alloys like 6061, 5052, or 7075

Tight Tolerances: Design with anodizing thickness in mind (especially for hard anodizing)

Controlled Surface Roughness: An Ra value between 0.2–0.8 µm is optimal

Partnering with Certified Surface Treatment Providers: Ensures quality compliance

5. Inspection and Quality Control in Surface Treatment

Post-anodizing quality inspection should include:

- Visual Inspection: To detect discoloration, peeling, or pits

- Microscopic Examination: For thin films or microscopic corrosion

- Thickness Measurement: Using eddy current or cross-section analysis

- Adhesion Testing: Tape test or bend test (ASTM B571)

- Sealing Quality: Using dye-penetrant or conductivity testing

For companies like YIXIN Precision, rigorous inspection protocols ensure consistent quality and surface aesthetics across batches.

6. How to Optimize Your Anodizing Workflow

- Automation: Use programmable process tanks and timers to reduce human error

- Bath Monitoring: Regularly check acid concentration, temperature, and conductivity

- Process Standardization: Implement SOPs for each stage

- Client Communication: Educate customers about anodizing limitations during DFM (Design for Manufacturability)

Conclusion

Understanding the surface treatment process and its link to anodizing defects is crucial for CNC machining professionals aiming for excellence in both function and appearance. A defect-free anodized surface doesn't just reflect good workmanship—it enhances product longevity, brand credibility, and customer satisfaction.

By identifying root causes and enforcing best practices in CNC machining and surface treatment, manufacturers can drastically reduce quality failures and rework costs.

anodising defects,Anodizing defects,CNC machining,surface treatment,types of anodizing,surface treatment process

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.