Resources

Resources

Acrylic CNC Machining: Precision, Clarity, and Efficiency with Professional CNC Acrylic Services

Introduction: The Power of Acrylic in Modern Manufacturing

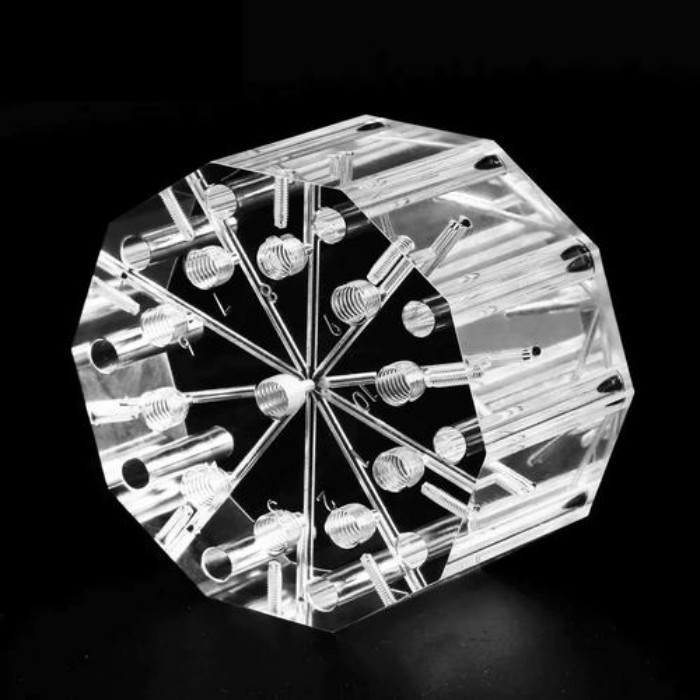

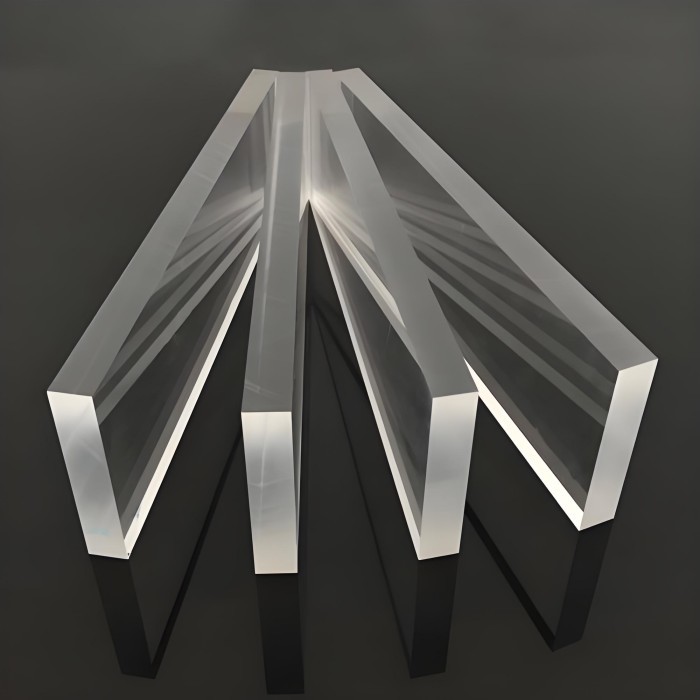

Acrylic, also known as PMMA (Polymethyl Methacrylate), has become one of the most popular plastic materials in precision machining due to its excellent transparency, weather resistance, and versatility. From optical lenses and display panels to medical instruments and decorative components, acrylic offers both functional and aesthetic advantages.

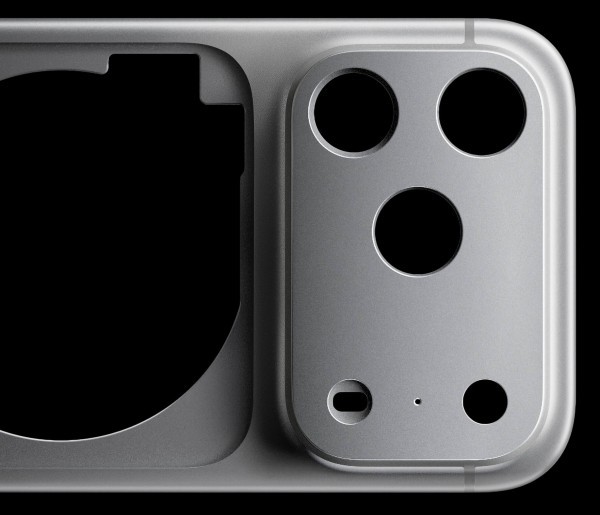

In today’s competitive manufacturing world, acrylic CNC machining plays a vital role in ensuring parts with tight tolerances, smooth surfaces, and consistent quality. Unlike manual cutting or molding, CNC machining allows designers and engineers to achieve complex geometries and precise dimensions, which are critical for industries such as electronics, robotics, medical devices, and aerospace.

This article explores the principles of acrylic CNC machining, compares it with laser cutting, and explains why YIXIN PRECISION, a trusted CNC machining supplier from Shenzhen, is the right partner for your next acrylic machining project.

1. What Is Acrylic CNC Machining?

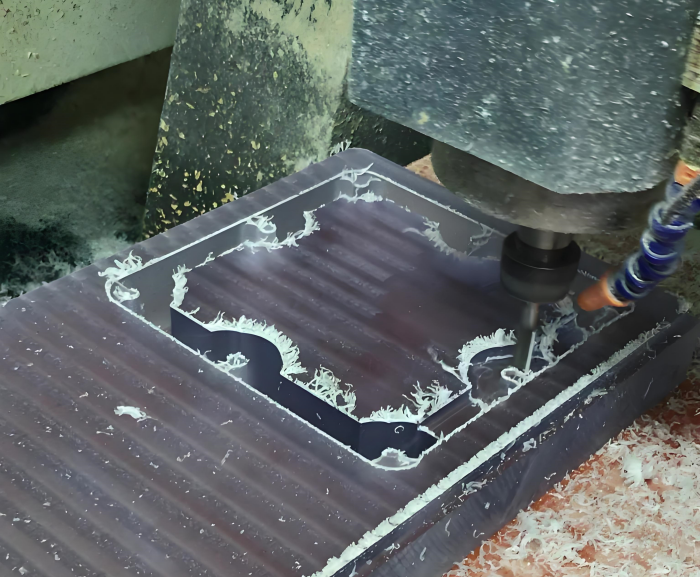

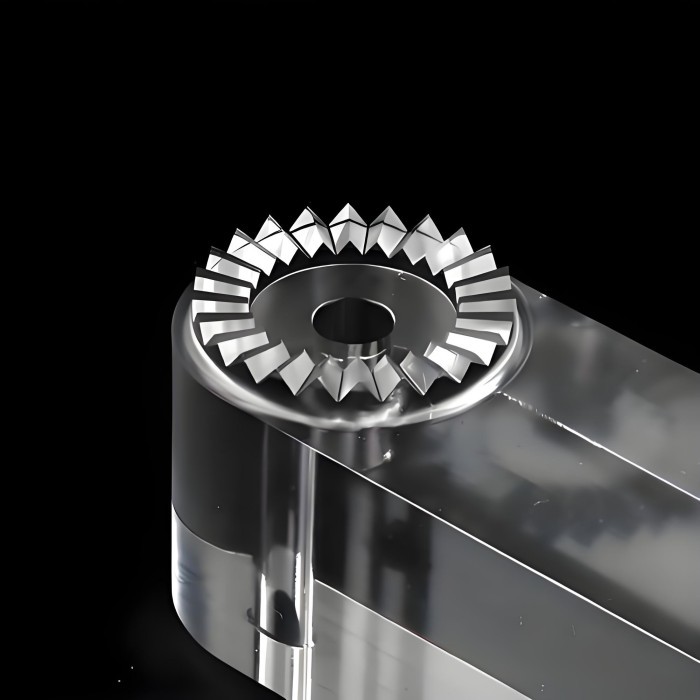

Acrylic CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to shape acrylic blocks into finished parts. It’s especially suitable for prototypes, low-volume production, and transparent components that require high dimensional accuracy.

Through precise programming and advanced tool paths, CNC acrylic machining can achieve:

-

Tight tolerances up to ±0.05 mm

-

Mirror-like surface finishes after polishing

-

Smooth edges without cracks or melting

-

Repeatable accuracy for multiple parts

The process typically involves milling, drilling, and engraving, all performed on high-speed CNC machines that minimize heat buildup — crucial for preventing acrylic deformation.

2. CNC Acrylic Service vs. Acrylic Laser Cutter

While both CNC machining and laser cutting are common methods for processing acrylic, they serve different purposes:

| Process | Advantages | Limitations | Best For |

|---|---|---|---|

| CNC Acrylic Machining | High dimensional accuracy, no burn marks, can cut thick blocks, supports 3D shapes | Slightly longer machining time | Complex parts, optical components, prototypes |

| Acrylic Laser Cutter | Fast, suitable for 2D outlines, smooth edge finish | Heat-affected zones, limited depth cutting, less accurate for thick sheets | Signs, panels, decorative parts |

👉 In short, CNC machining is ideal when precision, mechanical fit, or optical clarity are the priorities, while laser cutting is better for flat designs and fast throughput.

3. Common Acrylic CNC Machining Materials

Different grades of acrylic materials are available for CNC machining, each with unique characteristics suited for various applications:

| Material Type | Features | Typical Applications |

|---|---|---|

| Clear Acrylic (PMMA) | Excellent transparency (up to 92% light transmission), easy to polish | Display covers, lenses, protective panels |

| Colored Acrylic | Wide color range, UV stable | Lighting fixtures, signage, art installations |

| Impact-Modified Acrylic | Improved toughness and crack resistance | Machine guards, automotive parts |

| Cast Acrylic vs. Extruded Acrylic | Cast acrylic offers better optical clarity and machinability; extruded acrylic is cheaper but softer | Precision optical parts vs. general applications |

Proper material selection ensures both aesthetic quality and dimensional stability during machining.

4. Challenges in Acrylic CNC Machining

Even though acrylic is easier to machine than metals, it still presents several challenges that require expertise:

-

Heat sensitivity — Excessive heat can cause melting or stress cracking.

-

Tool wear — Dull tools leave marks or cloudy surfaces.

-

Chip removal — Poor chip evacuation may cause surface scratches.

-

Polishing requirement — Transparent parts often need post-process polishing for optical clarity.

To overcome these, a reliable CNC acrylic service provider uses optimized cutting parameters, sharp carbide tools, and air or coolant-assisted machining.

5. Why Choose YIXIN PRECISION for Acrylic CNC Machining

Based in Shenzhen, China, YIXIN PRECISION has over 20 years of experience in high-quality CNC machining of both metal and plastic parts, serving industries such as robotics, aerospace, medical, and automation.

Here’s why YIXIN stands out:

-

🧠 Advanced Equipment: Over 30 sets of CNC machines, including 5-axis machining centers for complex geometries.

-

🔍 Strict Quality Control: ISO 9001 and ISO 13485 certified for consistent quality and medical-grade precision.

-

⚙️ Material Expertise: Skilled in machining PMMA, PEEK, PC, ABS, and other plastics.

-

⚡ Fast Prototyping & Delivery: Capable of rapid sample production and on-time shipment worldwide.

-

🧩 One-Stop Service: From CNC machining and laser cutting to surface treatment and assembly.

Whether you need acrylic prototypes, optical display housings, or precision transparent components, YIXIN ensures clarity, precision, and repeatability in every piece.

6. Applications of CNC Acrylic Parts

Acrylic CNC parts are widely used in industries where transparency and precision are key:

-

Medical: Diagnostic device covers, surgical light diffusers

-

Robotics: Transparent sensor housings and camera covers

-

Aerospace: Instrument display panels and light lenses

-

Consumer Electronics: Transparent cases and display windows

-

Advertising: Custom signage and illuminated logos

Each project benefits from the tight tolerance control and optical-grade finishing achievable only through professional CNC machining.

Conclusion

Acrylic CNC machining combines precision engineering with aesthetic excellence. By choosing a trusted manufacturer like YIXIN PRECISION, you can ensure every acrylic part meets the highest standards of clarity, accuracy, and durability — from prototype to mass production.

Whether you’re comparing CNC acrylic services, choosing acrylic machining materials, or evaluating an acrylic laser cutter option, YIXIN’s technical team can guide you to the best solution tailored to your design needs.

acrylic cnc machining,cnc acrylic service,acrylic cnc machining materials,acrylic laser cutter

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.