Resources

Resources

Plastic Injection Molding vs. 3D Printing: Costs, Benefits & Smart Choices for Your Next Product

Introduction

In today’s competitive manufacturing world, understanding Plastic Injection Molding, 3D Printing, Injection Molding Cost, and 3D Printing Cost is crucial for product designers, engineers, and buyers. Whether you’re producing high-volume consumer goods or low-volume prototypes, the right process can make or break your project’s profitability. This article explains these technologies with data-backed insights and ends with how Shenzhen Yixin Precision supports global customers with customized metal and plastic parts.

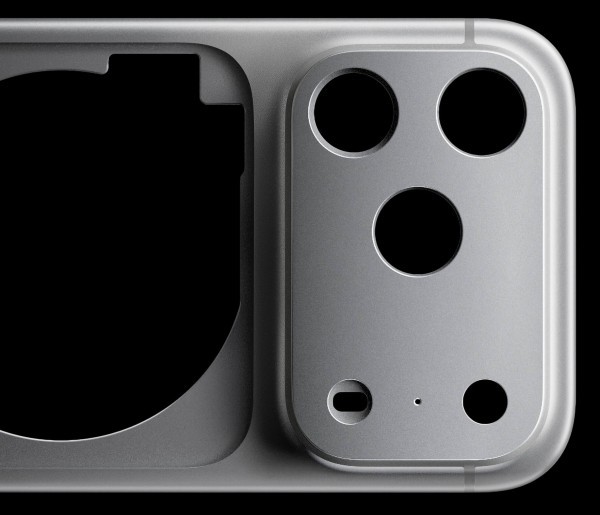

1. Plastic Injection Molding – The Backbone of Mass Production

Plastic Injection Molding is one of the most widely used manufacturing processes for producing plastic parts. It works by melting thermoplastic material and injecting it into a metal mold cavity under high pressure. After cooling, the part is ejected with high dimensional accuracy.

Key Advantages:

-

High Volume Efficiency: Perfect for thousands to millions of parts.

-

Consistent Quality: Repeatable results with tight tolerances.

-

Material Versatility: From ABS and PP to engineering plastics like PEEK or Nylon.

-

Surface Finishing: Smooth or textured surfaces directly out of the mold.

Limitations:

-

High Upfront Tooling Cost: Molds can cost from $3,000 to $50,000 depending on complexity.

-

Longer Lead Times for Tooling: 2–8 weeks for mold manufacturing.

2. 3D Printing – Flexibility for Prototypes and Low Volume

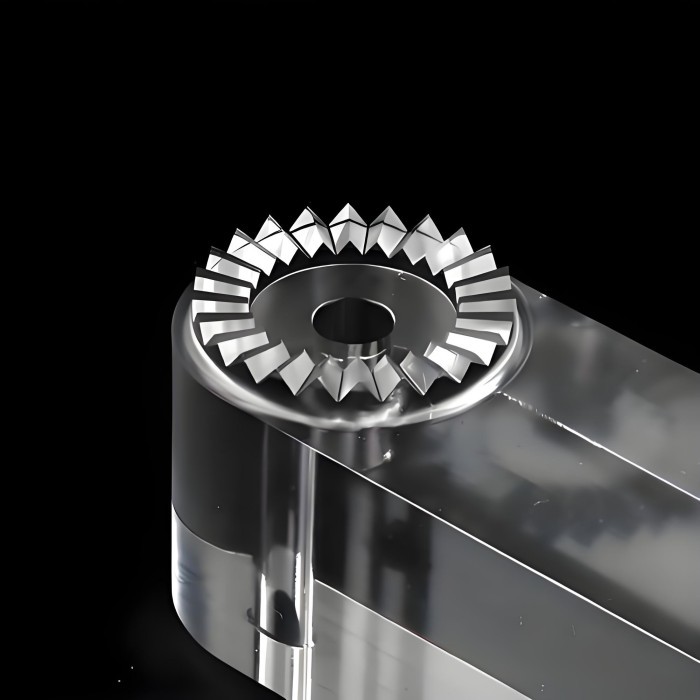

3D Printing (additive manufacturing) builds parts layer by layer without tooling. It’s ideal for design validation, functional prototypes, and complex geometries.

Key Advantages:

-

No Tooling Required: Immediate production from CAD files.

-

Highly Customizable: Supports unique shapes impossible with traditional methods.

-

Fast Iteration: Design changes can be implemented overnight.

-

Material Range: Plastics, resins, metals, composites.

Limitations:

-

Unit Cost Increases with Volume: Not cost-efficient for large production runs.

-

Surface Quality & Strength: May require post-processing; mechanical properties may be lower than injection molded parts.

3. Injection Molding Cost vs. 3D Printing Cost

Understanding cost drivers is key to making the right choice. Below is an illustrative comparison (in USD) for a medium-sized part (100mm × 60mm × 30mm) using ABS material:

| Production Volume | Injection Molding Cost per Part | 3D Printing Cost per Part |

|---|---|---|

| 1 piece | $5,000 (mold) + $2 per part = $5,002 | $80 |

| 100 pieces | $5,000 (mold) + $2 per part = $52 per part | $40 |

| 1,000 pieces | $5,000 (mold) + $2 per part = $7 per part | $25 |

| 10,000 pieces | $5,000 (mold) + $2 per part = $2.5 per part | $20 |

Insights:

-

Low Volume (<100): 3D printing is cheaper and faster.

-

Medium Volume (100–1,000): Small-batch injection molding can compete.

-

High Volume (>1,000): Injection molding wins on cost per part.

4. How to Decide Between the Two

-

Product Stage: For prototyping or early design, 3D printing saves time. For mass production, injection molding lowers cost per part.

-

Complexity: Highly intricate internal structures are easier with 3D printing.

-

Budget & Timeline: If you can afford upfront mold costs and longer setup, injection molding pays off.

Tip: Many companies adopt a hybrid strategy—use 3D printing for prototypes, then shift to injection molding for scaling production.

5. Trends in Costs and Lead Times (2025 Outlook)

According to global manufacturing surveys (Wohlers Report & Statista):

-

Average 3D Printing Cost Reduction: Prices per part dropped by 15% in the last 3 years due to faster machines and cheaper materials.

-

Injection Molding Lead Time Improvements: Rapid tooling and aluminum molds can cut lead times from 6 weeks to 2 weeks.

-

Asia Advantage: China and Southeast Asia offer 30–60% lower tooling and production costs than North America or Europe.

6. Case Example – A Mid-Sized Consumer Electronics Housing

-

Tooling in China: $4,500 mold cost; $1.80 per part for 5,000 units.

-

Tooling in USA: $15,000 mold cost; $3.50 per part for 5,000 units.

-

3D Printing Globally: $25–$45 per part depending on material and finish.

This illustrates how the right sourcing region significantly affects cost structure.

7. Shenzhen Yixin Precision – Your One-Stop Metal & Plastic Parts Partner

At Shenzhen Yixin Precision, we specialize in custom metal and plastic parts manufacturing for over 20 years, combining CNC machining, Plastic Injection Molding, 3D Printing, and Surface Treatments.

Why Customers Choose Yixin Precision:

-

Comprehensive Capabilities: From rapid prototyping to mass production of metal and plastic parts.

-

Small-Batch Injection Molding Services: Lower tooling costs and fast turnaround for startups and new product launches.

-

ISO-Certified Quality: Meeting aerospace, medical, robotics, and consumer electronics standards.

-

Global Export Experience: Serving customers across North America, Europe, and Asia with reliable delivery.

-

Engineering Support: Our team advises on design-for-manufacturing to reduce cost and time-to-market.

By leveraging our integrated services, clients can move seamlessly from prototype to production, minimizing supply chain risks and maximizing product success.

Plastic Injection Molding,3D printing,Injection Molding Cost,3D printing Cost

Related News

Privacy Disclosure and Data Protection

In Yixin Precision Metal and Plastic Ltd., we prioritize the protection of our customers' and visitors' privacy. As a responsible company, it is our utmost priority to ensure that all personal data is treated confidentially and used in accordance with applicable data protection laws.

What does Privacy Disclosure mean to us?

Privacy disclosure is not just a legal obligation for us; it is a principle to which we are dedicated. We commit to treating any information entrusted to us during our business relationships with the utmost confidentiality. This includes both personal data of our customers and business information and trade secrets.

How we protect your data

To ensure the security of your data, we employ state-of-the-art technologies and security measures. Our systems are designed to prevent unauthorized access, misuse, or loss of your information. Additionally, we regularly train our employees on handling sensitive data and data protection regulations to maintain the highest standards.

Disclosure of information

We do not disclose personal data of our customers or visitors to third parties unless express consent is given or we are legally obligated to do so. In cases where we engage service providers or partner companies for data processing, we ensure that they also adhere to strict data protection standards.

Your rights

As a customer or visitor, you have the right to access, correct, delete, or restrict the processing of your data. Please contact us if you have any questions about our privacy practices or if you wish to exercise your rights.

Changes to this Privacy Policy

We reserve the right to change or update this privacy policy at any time. Please check this page regularly for updates.

Contact Us

If you have any questions or concerns about our privacy practices, please do not hesitate to contact us. We are here to assist you.

Yixin Precision Metal and Plastic Ltd Code of Conduct

In Yixin Precision Metal and Plastic Ltd, we place great emphasis on integrity, ethical behaviour, and professionalism in all our endeavours. Our Code of Conduct forms the backbone of our corporate culture and obligates all employees and partners to uphold the highest standards regarding business practices, work environment, and social responsibility.

1. Integrity and Ethics

We commit to acting honestly, fairly, and transparently. Our actions are always guided by the highest ethical principles, and we avoid any form of fraud, bribery, corruption, or unfair business practices.

2. Respect in the Workplace

We value diversity and foster a work environment characterized by respect, tolerance, and appreciation. Discrimination, harassment, or any form of inappropriate behaviour are not tolerated.

3. Data Privacy and Confidentiality

We respect the privacy of our customers, employees, and business partners and treat all information confidentially. Personal and business data are protected in accordance with applicable data protection laws and our internal policies.

4. Quality and Customer Satisfaction

We strive for excellence in product quality and customer service. Our aim is to exceed the needs and expectations of our customers and build long-term, trusting relationships.

5. Environmental Responsibility

We are mindful of our responsibility to the environment and aim for sustainable business practices. We strive for resource efficiency, waste minimization, and compliance with environmental regulations.

6. Social Responsibility

We actively contribute to the well-being of the communities in which we operate. Through voluntary efforts, donations, and other initiatives, we support social projects and contribute to positive change.

7. Compliance with Laws and Regulations

We strictly adhere to all applicable laws, regulations, and standards in the countries where we operate. We are committed to a high level of compliance and integrity in all our business activities.

At Yixin Precision Metal and Plastic Ltd, the Code of Conduct is more than just a document; it is a promise we make to our employees, customers, suppliers, and society as a whole. We take our responsibility seriously and strive to achieve the highest standards every day.